A rock crusher is a heavy-duty machine designed to break down large rocks into specific sizes of aggregate, from coarse gravel to fine sand. These robust machines come in various configurations—from portable mobile units to high-capacity stationary plants—to suit different job sites and production needs. The right configuration and type of crusher hinge directly on the hardness of your rock and the final material specifications you aim to produce. Understanding these different types is the essential first step in selecting the most efficient and cost-effective solution for your project.

Types of Rock Crushers: Mobile & Stationary

Rock crushers can be broadly divided into two main categories based on their mobility and setup: mobile crushers and stationary plants. Understanding the different types of rock crushers is essential for selecting the rock crusher for sale for your specific project needs, rock characteristics, and production goals.

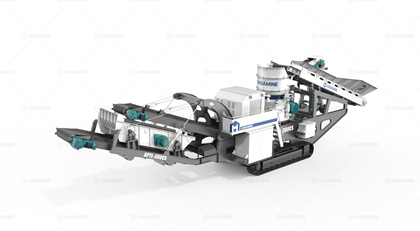

Mobile Crushers: High-Flexibility Solutions

Mobile crusher rock for sale offers exceptional flexibility, making them ideal for projects requiring frequent relocation or on-site crushing. They are available as both individual portable units and integrated crushing-and-screening plants.

Featured Mobile Combination Plants

Beyond single units, our advanced integrated mobile rock crushers for sale offer unmatched efficiency and control for complex on-site tasks.

Stationary Crushing Plants: High-Capacity Rock Processing Solutions

For large-scale quarrying, mining, and industrial operations requiring maximum output and long-term reliability, stationary rock crushing machines form the foundation of continuous production. Unlike mobile rock crusher mining units, these permanent installations are engineered for decades of high-volume service, delivering the lowest cost per ton for large-scale aggregate production. A complete rock crushing plant is a custom-engineered system that integrates multiple machines into an efficient processing circuit.

Complete Stationary Crushing Plant Solutions

A well-designed stationary rock crusher machine system is more than a single machine; it’s a synchronized process that typically operates across three core stages to transform raw quarry rock into precise, marketable aggregates.

Primary Crushing Station: This first stage is designed for brute force, reducing massive raw feed from the quarry face down to manageable sizes. This station is invariably built around a robust jaw crusher, chosen for its ability to handle the largest, most abrasive rocks like granite and basalt. The output from this stage is typically 6- to 8-inch rock, which is then conveyed to the secondary stage.

Secondary Crushing Station: Here, the focus shifts from raw size reduction to refining the product and beginning to shape the aggregates. This stage further reduces the material from the primary crusher and is essential for achieving proper product gradation. Cone crushers are the most common choice here for hard and abrasive stone, prized for their reliability and ability to produce a well-graded, cubical product. The design of this station often includes large screening units to separate material that is already to size, improving overall plant efficiency.

Tertiary & Quaternary Crushing Station: For operations requiring precisely shaped specialty products or manufactured sand, a third (and sometimes fourth) crushing stage is incorporated. This stage utilizes specialized cone crushers configured for fine crushing or high-speed Vertical Shaft Impact (VSI) crushers. VSI crushers are unparalleled for shaping aggregate, producing highly cubical products, and fracturing stone to create high-quality concrete sand, making them a critical component in modern rock crushing plants.

Key Stationary Crusher Units

Within these plant systems, individual crushers are selected for their specific role and performance characteristics.

Stationary Jaw Crushers: The undisputed workhorses of primary crushing. These heavy-duty jaw type rock crushers are characterized by their large feed openings, massive frames, and unwavering reliability under constant, extreme stress. They are the cornerstone of any hard rock stationary crushing operation, built to process the toughest materials.

Stationary Cone Crushers: The precision instruments of the crushing circuit. Available in secondary and tertiary models, stationary cone crushers offer exceptional control over the final product size and shape. Modern hydraulic systems allow for quick adjustment of the crusher’s setting under load, ensuring consistent output and protecting the machine from tramp metal or uncrushable objects. They are the ideal choice for producing high-value aggregate for asphalt and concrete.

Stationary Impact Crushers: The preferred choice for processing softer, less abrasive rock like limestone and recycled concrete materials. Stationary impact crushers offer high reduction ratios and excellent product shape in a single machine. Their ability to handle slabby material and produce a well-shaped, cubical product makes them ideal for asphalt and concrete aggregate production without the need for multiple crushing stages.

Material Characteristics: Designing the Optimal Crushing Circuit

The foundation of an efficient and cost-effective operation begins not with the machine, but with the material. The specific characteristics of your rock—its hardness, abrasiveness, compressive strength, and moisture content—are the primary drivers behind selecting the right rock crusher and configuring the entire crushing circuit. A configuration perfectly suited for soft limestone will be inefficient and costly when processing hard granite. This guide outlines how to match your rock crushing equipment to your material for maximum productivity and minimal wear.

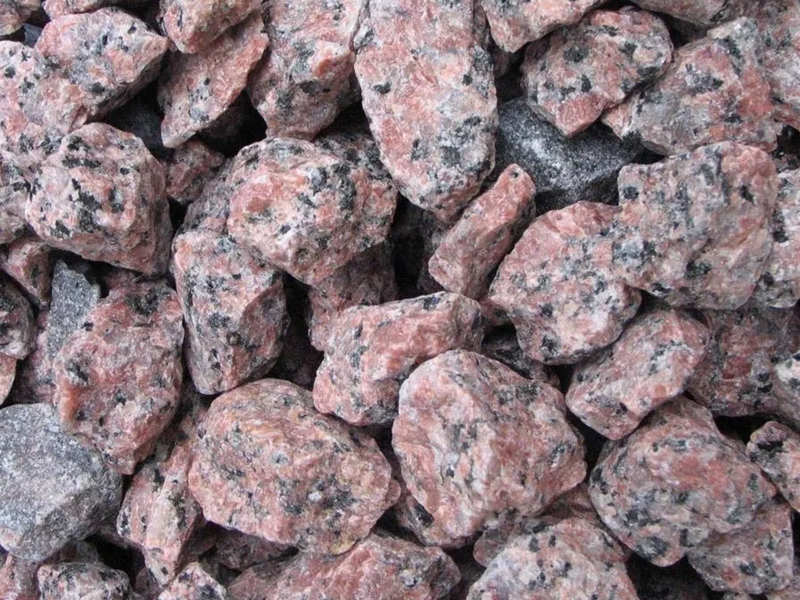

Hard & Highly Abrasive Rock (Granite, Basalt, Quartzite)

These igneous and metamorphic rocks are among the toughest materials to process. Characterized by high compressive strength (often over 200 MPa) and significant quartz content that makes them highly abrasive, they require equipment designed for extreme wear resistance and powerful compressive force. Their interlocking crystalline structure demands massive force to fracture, making them unsuitable for impact-dominated crushing methods.

- Optimal Configuration: The industry-standard jaw crusher + cone crusher circuit is mandatory. The mechanical, compressive force of a primary jaw crusher is the most effective method for initial size reduction. A secondary cone crusher is then essential for further reduction via inter-particle crushing, which produces a well-graded product while managing abrasion.

- Key Consideration: The focus is on utilizing machines built with heavy-duty frames and high-quality manganese steel wear parts to manage extreme compressive forces. Impact crushing is generally unsuitable due to excessively high wear rates.

Medium-Hard to Hard Rock (Limestone, Dolomite, Sandstone)

This diverse category encompasses sedimentary rocks with a wide range of hardness and abrasiveness. Limestone and dolomite typically have lower abrasiveness but can vary significantly in hardness, while sandstone’s abrasiveness depends on its quartz content. These materials are often friable, meaning they break along natural cleavage planes, allowing for more flexibility in crushing methods compared to granite.

- Optimal Configuration: A jaw crusher remains the optimal primary crusher. The choice of secondary crushing, however, depends on the product goal:

- For high-volume production of a consistent, graded product, a cone crusher is the preferred choice.

- When a highly cubical product shape is the top priority (e.g., for asphalt chips), a secondary impact crusher is an excellent alternative due to its superior shaping capabilities.

- Key Consideration: The abrasiveness is manageable for both cone and impact crushers, allowing the selection to be driven by the specification of the final product.

Soft & Low-Abrasion Rock (Weathered Limestone, Shale, Recycled Concrete)

This category includes materials that are friable, non-abrasive, and often have lower compressive strength. Weathered limestone and shale are soft, layered sedimentary rocks that break easily. Recycled concrete and asphalt millings are composite materials containing hardened cement paste and aggregates, which are relatively soft but may contain occasional, unpredictable abrasive elements. These materials are ideal for high-volume processing with minimal wear.

- Optimal Configuration: Simpler circuits are highly effective. A primary impact crusher can often handle the entire reduction process in a single stage. For larger feed size or higher capacity, a jaw crusher + impact crusher combination provides excellent control over the final product’s size and shape.

- Key Consideration: The low abrasiveness allows for longer wear part life in impact crushers. The key advantage is the ability to achieve a high-quality product in fewer stages, significantly reducing both capital and operational costs.

There is no universal solution. The most efficient and profitable operation is built by first understanding the material and then designing the crushing circuit around it. Consulting with our experts for a thorough analysis of your specific rock sample is the critical first step toward configuring a system that delivers the lowest cost per ton.

Rock Crushers Solutions – Professional Design

We have successfully solved rock crushing needs for many customers. Below I will share a few rock crushing solutions for you:

350t/h For Cobblestone

- Capacity: 350T/H

- Finished Product(mm): 5-10, 10-20, 20-25

- Configuration: Vibrating Feeder, Rock Cone Crusher, Vibrating Screen, etc.

- Application: Quarry

80t/h For Volcanic Rock

- Capacity: 80T/H

- Crusher Model: Cone Crusher

- Finished Product(mm): 0-20

- Application: Production and sale of sand and gravel aggregates.

150t/h For Granite

- Capacity: 150T/H

- Finished Product(mm): 5-10, 10-20

- Configuration: Vibrating Feeder, Cone Crusher, Screen Machine, etc.

- Application: Road construction

200t/h For Cobblestone

- Capacity: 200T/H

- Finished Product(mm): 80-100mm

- Configuration: Jaw Crusher, Screen Machine, PLC Control Box, etc.

- Application: Road construction

180t/h For Marble

- Raw Material: River Stone

- Capacity: 180T/H

- Finished Product(mm): 10-20, 20-30

- Configuration: Crawler Jaw Crusher, Crawler Screen Plant etc.

- Application: Quarry

What’s more, in this year, we also customized suitable solutions for hundreds of customers’ projects in highways, high-speed railways, water conservancy projects, municipal construction, sand and gravel materials, concrete mixing plants and other industrial fields. After the installation, I will share with you.

Industry Applications of Rock Crushing Technology

Rock crushing equipment serves vital roles across multiple sectors where raw materials need transformation into usable products. These powerful machines address fundamental processing needs in various industrial contexts, enabling infrastructure development and resource utilization.

Mining OperationsIn both surface and underground mining, crushing systems handle size reduction of metallic ores and industrial minerals. The equipment processes extracted materials to specifications required for further mineral extraction and beneficiation processes, supporting the initial stages of raw material production.

Gold Mining SectorGold mining operations utilize crushing technology of rock crusher for gold to reduce quartz-based ores to particle sizes optimal for gold liberation. The process enables efficient metal recovery through subsequent processing stages, serving both large-scale mining operations and smaller extraction projects.

Quarry OperationsAggregate production facilities employ crushing systems to transform extracted bedrock into specified construction materials. These operations produce graded aggregates essential for concrete production, asphalt mixtures, and various construction applications, forming the foundation of building material supply chains.

Construction ProjectsMajor infrastructure development utilizes mobile crushing solutions for on-site material processing. This approach allows contractors to process excavated materials and demolition debris directly at project locations, reducing transportation requirements and enabling material reuse in road construction, foundation works, and other building applications.

Recycling IndustryCommercial recycling operations employ crushing equipment to process construction and demolition waste into reusable aggregates. This application supports sustainable building practices by converting waste materials into valuable resources for new construction projects, reducing environmental impact through material conservation.

Industrial Materials ProductionSpecialized manufacturing operations use precision crushing to create engineered materials for specific applications. This includes production of railroad ballast, erosion control stone, and other industrial materials requiring exact particle specifications and performance characteristics.

Start a Rock Crusher Business: Step by Step

Launching a rock crushing business requires careful planning, strategic investment, and a clear understanding of the industry. A well-structured rock crusher plans can help you navigate the complexities, from initial setup to daily operations. Investing in high-quality equipment might involve a higher upfront cost but leads to greater reliability, lower operating expenses, and a better return on investment over time.

Step 1: Research and Planning

Market Analysis: Identify local demand for aggregates. Potential clients include construction companies, road builders, and infrastructure projects.

Business Model: Decide between operating a fixed quarry (for high-volume, long-term production) or offering mobile crushing services (for flexibility and on-site recycling).

Regulatory Compliance: Obtain necessary permits and licenses early. These typically include a business license, environmental permits, and mining or operation approvals from local authorities. The cost for these permits is generally manageable but requires time and attention.

Step 2: Financial Planning

Understanding both initial investment and ongoing operational costs is crucial for your rock crushing business. You should not only pay attention to rock crusher machine price, but also the cost of the whole process.

| Cost Category | Description | Considerations for Long-Term Economy |

|---|---|---|

| Initial Investment | Includes equipment purchase, site preparation, and licensing costs. | High-quality equipment may cost more upfront but offers better durability, efficiency, and higher resale value, reducing long-term costs. |

| Operational Costs | Recurring expenses such as energy consumption, wear parts replacement, maintenance, and labor. | Efficient equipment and preventive maintenance can significantly reduce energy and parts consumption, lowering the cost per ton. |

Step 3: Equipment Selection

Choose the Right Crusher: How to choose a rock crusher? Select equipment based on the material you’ll process (e.g., rock crusher jaws for hard rock, cone crushers for secondary crushing, impact crushers for softer materials or recycling).

Mobile vs. Stationary: Mobile crushers offer flexibility for multiple sites or on-site recycling, while stationary plants are suited for high-volume, fixed-location production.

Supplier Selection: Partner with reputable rock crusher manufacturers known for reliability, good aftersales service, and readily available spare parts.

Step 4: Operation and Management

Efficient Production: Focus on optimizing output and minimizing downtime. Regular maintenance is key to sustaining equipment performance and lifespan.

Cost Control: Monitor your cost per ton produced. This helps in assessing profitability and identifying areas for improvement.

Safety and Training: Prioritize operator training and safety protocols to ensure smooth and safe site operations.

Building a successful rock crushing business hinges on thorough rock crusher plans, smart investment in equipment, and efficient operations. Focusing on these elements will help you establish a profitable and sustainable operation.

Rock Crusher Videos

These are some of our videos on rock crusher youtube. Check if you want to see the rock crushing equipment for sale in motion.

Our Expertise & Partnership Opportunities

Mining Equipment Solutions Expert

ANDAMINE stands as one of the leading rock crushing equipment manufacturers with a proven track record of excellence. Since our establishment, we have delivered over 150 complete solutions to customers worldwide, including customized crushing lines, mobile crushing plants, and sand making production lines. Our mission is to help clients succeed through advanced technology, superior quality, and reliable service, making us your trusted partner in mining and construction equipment solutions.

Collaborative Project Development

Located in Zhengzhou, the industrial heart of China’s Henan province, ANDAMINE combines manufacturing excellence with engineering expertise. Our professional team works closely with clients to develop customized solutions based on specific project requirements:

We require the following information to provide optimal equipment recommendations:

Material characteristics and rock properties

Required production capacity and final product specifications

Site conditions and operational preferences

Budget parameters and project timeline

Global Partnership Program

ANDAMINE welcomes inquiries from qualified companies interested in representing our crushing equipment solutions worldwide as rock crusher dealers. We invite established equipment suppliers and industry professionals to join our growing network of authorized partners. Contact us today to discuss how we can collaborate to serve your local market with quality crushing equipment solutions.