Crusher plant in Bolivia is essential for turning the country’s rich mineral resources into usable construction materials. Bolivia, known for Potosí silver, tin, and vast lithium reserves, is seeing rapid urban growth and major infrastructure projects, including roads, bridges, and housing. With rising demand for aggregates, understanding the opportunities, challenges, and investment strategies for crusher plants is key for mining companies, construction firms, and investors entering this growing market.

Market Overview: Rising Demand for Crusher Plants in Bolivia

Mining and Construction GrowthBolivia’s crusher plant market is growing rapidly, driven by both mining and construction sectors. Rich mineral reserves—such as lithium, iron, tin, and silver—attract domestic and foreign investment. Urbanization and large-scale infrastructure projects are boosting demand for construction aggregates. Government plans for over $2 billion in infrastructure projects over the next five years highlight the sustained need for reliable aggregate production.

Government Infrastructure ProgramsNational infrastructure programs encourage the use of locally sourced materials and support aggregate crushing plants. Bolivia consumes over 20 million tons of aggregates annually, with expected growth of 5–7% per year. These projects create a stable market for crushed stone, sand, and gravel while promoting long-term investment opportunities.

Market Opportunities for InvestorsThe rising demand opens opportunities for both stationary and mobile crusher plants. Flexible solutions are particularly needed in remote or mountainous regions, where access is limited. Understanding market dynamics, resource availability, and government policies is crucial for investors aiming to capitalize on Bolivia’s growing need for reliable crusher operations.

Now that we’ve explored the strong demand for crushing plants in Bolivia, you might wonder: where exactly can these plants operate most efficiently? Let’s take a closer look at Bolivia’s mineral and construction stone resources, as well as the terrain and infrastructure that shape operational feasibility.

Resource Base and Geographical Landscape of Bolivia

Abundant Mineral Resources

Bolivia possesses extensive mineral resources, providing a stable foundation for crusher plant operations. The Uyuni region alone holds over 9 million tons of lithium, while iron, tin, zinc, and silver are distributed nationwide. These reserves ensure a reliable supply for mining-related crushing operations and long-term production stability, supporting investor confidence.

Construction Stone Availability

In addition to minerals, Bolivia offers vast construction stone reserves such as granite, limestone, basalt, and river pebbles. Regions like La Paz, Santa Cruz, and Potosí supply high-quality materials for roads, bridges, and buildings. This availability allows for strategically located crushing plants serving both mining and construction industries efficiently.

Terrain and Accessibility

Bolivia’s diverse geography presents both challenges and opportunities. Mountainous highlands complicate transport and installation, while lowland regions provide better access to roads, power, and water. Mobile or modular crusher systems offer flexibility for high-altitude or remote areas, whereas stationary plants are suitable for well-connected sites with high throughput.

Infrastructure and Logistics

Ongoing infrastructure improvements, such as the Bi-Oceanic Railway Corridor, enhance connectivity between resource-rich areas and construction hubs. Reliable transport networks reduce operational costs and improve project timelines, making efficient and sustainable crusher plant operations feasible across various regions.

With a clear understanding of Bolivia’s abundant resources and diverse terrain, you may ask: which types of crusher plants are best suited for these regions and project requirements? Understanding the right equipment is key to maximizing efficiency and ROI.

Types of Crushing Plants Suitable for Bolivia

Bolivia’s diverse geography and rich mineral resources call for different types of crushing plants to support mining, construction, and infrastructure projects. Choosing the right plant depends on factors such as ore type, terrain, project size, and mobility needs. Andamine provides both stationary and mobile crushing plants to meet various project requirements, ensuring efficient and reliable material processing across different conditions.

Stationary Crushing Plants – For Large-Scale and Long-Term Projects

Stationary crushing plants in Bolivia are ideal for large-scale mining operations and long-term infrastructure projects and beyond. These plants deliver high production capacity, stable output, and exceptional durability, making them well-suited for processing hard materials such as iron, tin, and granite. Andamine provides customized stationary crushing solutions tailored to different project requirements and site conditions.

Flexible Configuration for Diverse Production Needs

- Crushing + Screening: Combines crushers and screening machines to separate materials into different sizes for final and intermediate products.

- Crushing + Sand Making: Integrates crushers with sand makers to produce high-quality construction sand for building and road projects.

- Crushing + Grinding: Pairs crushers with grinding mills to create fine powders for industrial applications.

These configurations enable more complex production processes, greater product variety, and stable, efficient output.

Concrete-Based Foundation

Most stationary crushing plants adopt reinforced concrete foundations for superior structural stability.

- Stronger and more durable than soil foundations, capable of supporting heavy equipment and absorbing vibration.

- Reduces machine shaking and deformation during continuous operation.

- Enhances equipment reliability and stability.

- Lowers maintenance and replacement costs.

- Extends service life, improving overall economic performance.

Foundation-Free Type

The foundation-free stationary plant eliminates the need for concrete construction and can be directly installed on a hardened floor or steel platform.

Features:

- Semi-mobile design allows quick installation, disassembly, and relocation.

- Lower vibration and noise ensure smoother, quieter operation.

Benefits:

- Reduces foundation investment and shortens construction time.

- Simplifies site relocation without rebuilding foundations, saving time and cost.

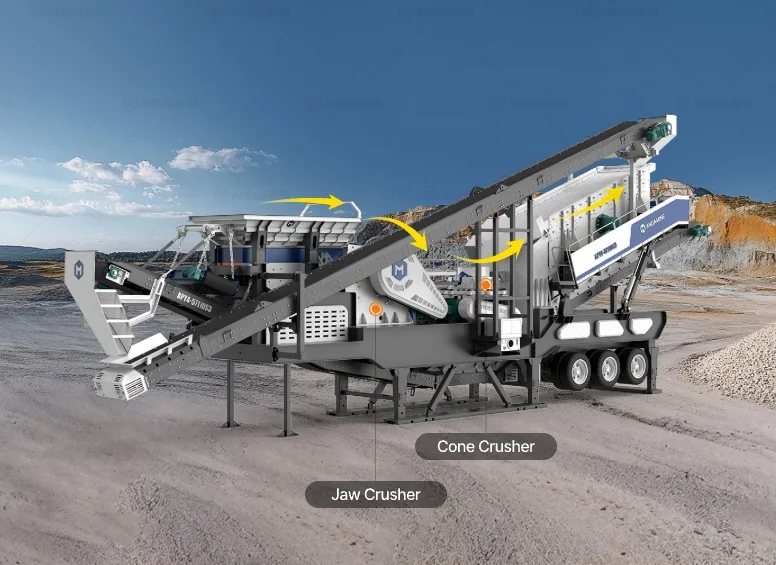

Mobile Crusher Plants – Fast Installation and Operation

For remote, high-altitude, or short-term projects, mobile crusher plants in Bilivia provide outstanding flexibility and fast setup. They are ideal for mountainous areas, scattered mining zones, or temporary construction projects requiring on-site crushing. Andamine offers both wheel-mounted and crawler-type mobile crushing plants, enabling efficient operation across diverse terrains and ensuring reliable performance even in challenging environments.

Wheel-Mounted Mobile Crushing Plant

The Andamine wheel-mounted mobile crushing plant is designed for flexible, fast, and cost-effective crushing operations. Built on a tire chassis, it allows easy relocation between job sites, making it ideal for projects that require frequent site transfers.

APY4-S 4 in 1 Mobile Crushing Plant

- Capacity: 30-200tph

- Feeder Size(mm): <500

- Output Size(mm): 5-80

APY3-F 3 in 1 Mobile Impact Crusher Plant

- Capacity: 50-350tph

- Feeder Size(mm): <700

- Output Size(mm): 5-180

Key advantages:

Flexible MobilityEasily moves between sites without the need for concrete foundations, saving 30–60 days of installation time compared to stationary plants.

Quick SetupEquipped with hydraulic legs and quick-mount shoes for synchronized lifting and stable positioning, significantly reducing installation time and costs.

Eco-Friendly OperationFeatures an integrated water spray dust suppression system to minimize dust emissions and ensure compliance with environmental standards at construction or mining sites.

Crawler-type Crushing Plant

The crawler crushing plant is mobile, reliable, and adaptable to all terrains. Equipped with top-brand engines and advanced hydraulics, it ensures stable, efficient operation. Its robust chassis provides high load capacity and excellent off-road performance.

APYL2-C Crawler Type Cone Crusher

- Capacity: 100-310tph

- Feeder Size(mm): <180

- Output Size(mm): 30-60

APYL2-J Track Mounted Jaw Crusher

- Capacity: 80-415tph

- Feeder Size(mm): <700

- Output Size(mm): 60-250

Key Advantages:

Flexible and Mobile

Tracked chassis with self-propelled capability allows easy relocation and on-site adjustments, saving time and reducing transport costs.

Performs efficiently on mountains, wetlands, deserts, and soft soil without extra foundation work, suitable for complex environments.

Equipped with Weichai or Cummins diesel engines and advanced hydraulic system, ensuring low fuel consumption, high stability, and continuous operation.

Full-rigid chassis with multiple tracks distributes weight, reduces ground pressure, provides high clearance, 360° rotation, strong load capacity, and excellent obstacle-crossing ability.

Recommended Crusher Plant Selection by Material and Terrain

The following table provides practical guidance on the most suitable crushing equipment types based on material, terrain, and project environment in Bolivia. It helps investors and companies quickly identify the right solution for specific conditions.

| Material / Raw Material | Terrain & Environment | Recommended Crusher Equipment / Plant Type | Reason for Recommendation | Capacity & Features |

|---|---|---|---|---|

| Lithium Ore (e.g., Salar de Uyuni) | High-altitude, remote areas | Crawler Mobile Crusher / Modular Mobile Plant | High mobility, suitable for rough terrain, on-site crushing reduces transportation cost | Track/wheel mobile crusher, jaw or impact crusher, medium capacity, ideal for dispersed ore points |

| Iron, Tin, Zinc Ore | Highland mines, concentrated deposits | Fixed High-Capacity Crushing Plant | Centralized resources, long-term operation, cost-effective | Jaw + cone crusher + vibrating screen, high capacity, continuous operation |

| Hard Construction Stone (Granite, Basalt) | Mountainous or lowland areas with stable power | Fixed or Semi-Mobile Crushing Plant | Hard materials require stable crushing; semi-mobile allows project flexibility | Jaw + cone/impact crusher, dust control system, high capacity, wear-resistant |

| Limestone, River Pebbles | Plains, riverside areas | Mobile / Semi-Fixed Crusher Plant | Flexible for temporary projects, short transport distance | Mobile jaw + cone crusher + screening, medium capacity, quick installation |

| Remote Mining Areas (Andes Mountains) | Rugged terrain, poor roads | Modular Crawler Mobile Crusher | Modular design for quick assembly, easy relocation | Track-mounted + modular screening, flexible layout, medium capacity, reduces transport cost |

| Urban & Road Construction Materials | Temporary construction sites | Small Mobile Crusher Plant | High flexibility, can be relocated according to site requirements | Small track or wheel mobile unit, easy operation, suitable for medium-to-low capacity |

Once you have determined the suitable crusher plant solution, the next step for any investor or project manager is understanding the associated costs and financial considerations. Proper planning ensures sustainable operations and attractive returns in Bolivia’s growing mining and infrastructure market.

Crusher Plant Costs and Financial Considerations in Bolivia

Investing in a crusher plant in Bolivia requires careful consideration of both capital expenditures and ongoing operational costs, as these directly influence profitability and long-term sustainability. Understanding the financial landscape helps investors make informed decisions and plan for efficient, cost-effective operations.

Capital Investment Highlights

The initial investment for a crusher plant includes several key components:

- Land and Site Preparation: Choosing a location near raw material sources or construction projects can significantly reduce transportation costs. Preparatory work may include site leveling, drainage solutions, and utility connections to ensure smooth operations.

- Civil Works and Supporting Infrastructure: Building strong foundations, equipment platforms, control rooms, and storage areas is necessary to maintain safety standards and operational efficiency.

- Equipment Procurement and Installation: Crushers, conveyors, screening systems, and dust control units form the core capital cost. The selection between stationary and mobile equipment affects both budget and flexibility for different project requirements.

- Training and Commissioning: Investing in workforce training ensures proper operation, reduces potential errors, and enhances safety compliance during plant startup.

The total crushing plant cost in Bolivia varies depending on scale, automation level, and plant configuration. While medium to large facilities require higher upfront investment, they offer increased production capacity and long-term revenue potential.

Operational and Ongoing Costs

Running a crusher plant involves recurring expenses that impact overall profitability:

- Energy and Fuel: Stationary crushing plants mainly use electricity, whereas mobile units may rely on hybrid diesel-electric power. Implementing energy-efficient technologies can lower operational costs.

- Maintenance: Regular inspection, wear part replacement, lubrication, and technical servicing are essential to prevent downtime and maintain optimal performance.

- Labor: Skilled operators, technicians, and administrative staff are required to ensure smooth, continuous operations.

- Environmental Management: Complying with Bolivian regulations for dust, water, and waste management increases costs but is crucial for sustainable and legally compliant operations.

Supplier Reliability and Equipment Selection

Choosing suppliers with proven track records and service networks reduces risks of delays, equipment downtime, and unexpected expenses. Reliable support ensures the plant runs efficiently and maintains financial predictability.

Financial Outlook and ROI

While initial costs can be significant, a well-managed crusher plant offers benefits such as reduced transportation costs, consistent material quality, and diversified revenue streams. Proper plant selection—stationary for large-scale operations or mobile for flexible sites—can achieve a payback period of 3–5 years, depending on project size and market demand.

Understanding costs is crucial, but equally important is knowing the potential risks. How might regulations, political changes, or market fluctuations affect your investment in Bolivia? This section highlights the key challenges investors face.

Investment Risks and Regulatory Environment in Bolivia

Establishing a crusher plant in Bolivia offers strong growth potential but requires careful management of regulatory, environmental, and operational risks. Understanding the country’s investment framework helps ensure compliance, stability, and long-term profitability.

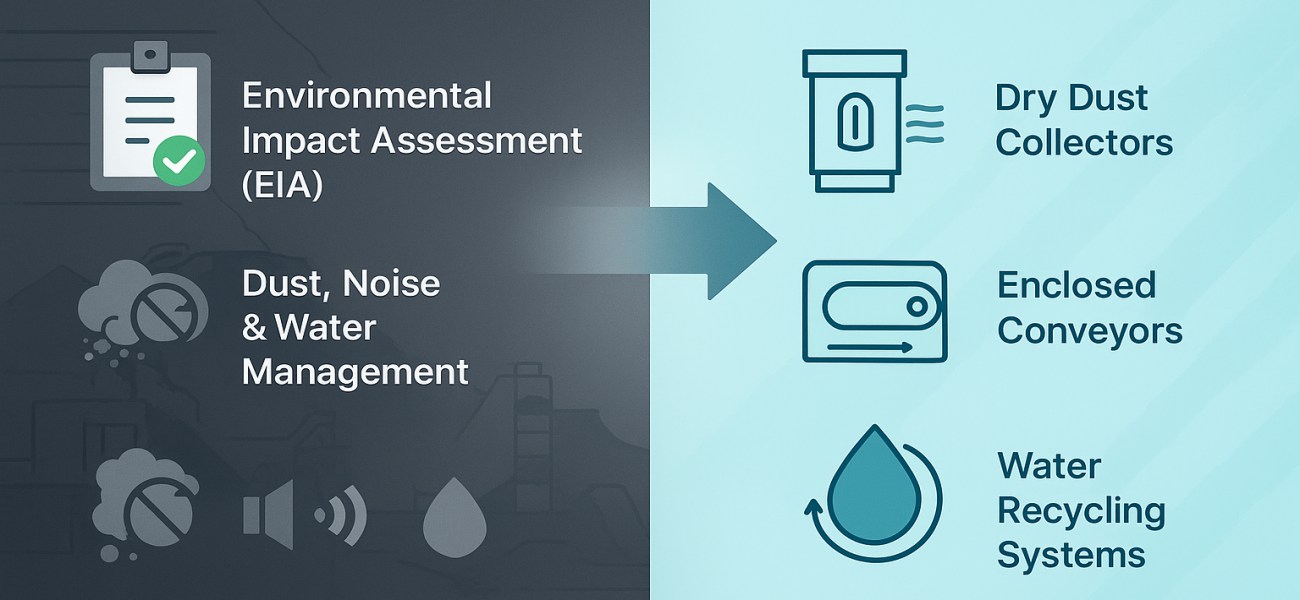

Environmental and Regulatory ComplianceCrushing plant teams should comply with Bolivia’s environmental laws, including completing an Environmental Impact Assessment (EIA) and managing dust, noise, and water emissions. The use of dry dust collectors, enclosed conveyors, and water recycling systems improves both compliance and efficiency.

However, policy adjustments and partial nationalization risks in the mining sector mean investors should maintain transparency and legal awareness to ensure operational continuity.

Social Responsibility and Community RelationsStrong community engagement—through local hiring, training, and development projects—is essential for gaining public trust and securing the social license to operate. Companies demonstrating social responsibility often enjoy smoother operations and better governmental relations.

Political, Logistical, and Market RisksBolivia’s political shifts, high-altitude logistics challenges, and market volatility tied to construction cycles may affect profitability. To mitigate these risks, investors should adopt mobile or modular crushing solutions, diversify supply networks, and maintain flexibility in business planning.

Knowing the risks allows you to plan proactively. What strategies and partnerships can help you navigate these challenges and achieve long-term success? Let’s explore practical approaches for investors in Bolivia’s crusher plant market.

Smart Strategies and Partnerships for Crushing Plant Investors in Bolivia

Investing in a crushing plant in Bolivia offers significant opportunities due to the country’s rich mineral resources and growing construction sector. However, success requires careful planning, strategic partnerships, and an understanding of local market dynamics.

Conduct Thorough Feasibility Studies

Before investing, assess the availability and quality of raw materials, transportation infrastructure, and project logistics. Feasibility studies help identify optimal sites, minimize transport costs, and ensure efficient operations. Understanding local regulations, including environmental requirements, is essential for compliance and smooth plant operation.

Build Strong Local Partnerships

Collaborating with local mining operators, construction companies, and government projects can provide access to resources, technical expertise, and regulatory guidance. Local partners help navigate administrative processes, secure consistent material supply, and reduce operational risks. Successful partnerships also enhance investor credibility in Bolivia’s mining sector.

Prioritize Community Engagement and Social Responsibility

Bolivia emphasizes community and environmental responsibility. Investors should focus on job creation, workforce training, and community development projects. Early engagement builds goodwill, strengthens social license to operate, and reduces potential conflicts that can disrupt operations.

Adopt Flexible Business Models

The Bolivian mining and construction market can be dynamic. Consider modular or mobile crushing plants, joint ventures, or contract-based operations. Flexibility allows adaptation to changing regulations, site conditions, or market demand, improving operational resilience and ROI.

Plan Implementation Strategically

Develop a step-by-step operational plan covering site selection, equipment procurement, workforce training, and commissioning. Integrate risk analysis, cost projections, and contingency measures to support informed decision-making and long-term success.

Future Trends: Smart, Modular, and Green Crushing Technologies

Flexible Deployment with Modular and Mobile Plants

- Modular crushing plants and mobile solutions allow quick setup and adaptability to varying site conditions.

- Ideal for mining and construction projects, they reduce downtime and optimize material flow.

Smart and Intelligent Crusher Plants

- Equipped with IoT sensors, automation, and intelligent monitoring systems.

- Enable real-time performance insights, predictive maintenance, and operational optimization.

- Improve safety, reliability, and efficiency.

Energy-Efficient and Low-Carbon Equipment

- Crushers designed for reduced energy consumption and lower carbon emissions.

- Support green mining initiatives in Bolivia by minimizing environmental impact.

Integration with Sustainable Construction and Circular Economy

- Facilitate recycling of aggregates and waste reduction.

- Promote adoption of eco-friendly practices across mining and construction sectors.

Industry Evolution and Future Outlook

- Combining modularity, intelligence, and sustainability positions companies and investors to stay competitive.

- Intelligent crushing plants represent the next generation of equipment for efficient and environmentally responsible operations.

Get Reliable Crusher Equipment with Andamine

Seize Bolivia’s booming mining and infrastructure market with smart, modular, and eco-friendly crusher plants. From large-scale stationary plants to flexible mobile units, Andamine delivers solutions that maximize productivity and profitability. Reach out to us now to secure reliable equipment and expert support, and make your next mining or construction project a success.