Quartz crushers transform one of Earth’s hardest minerals into precisely graded material for critical industries like solar glass and semiconductors. These quartz stone crushers overcome quartz’s Mohs 7 hardness through specialized crushing technology, delivering optimized particle sizes while minimizing operational costs.

What Is Quartz

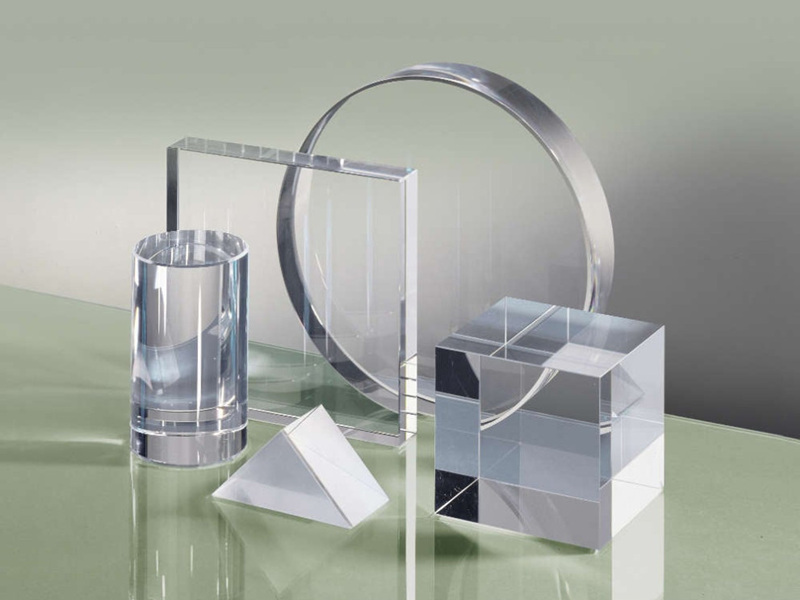

Quartz is one of the most abundant and versatile minerals on Earth, prized for its durability, chemical stability, and wide range of industrial uses. Below is an organized overview of quartz’s fundamental characteristics and how it transforms into valuable crushed products for various applications:

- Mineralogical Definition: Quartz is a crystalline form of silicon dioxide (SiO₂) that typically appears as hexagonal prisms or massive granular aggregates. It ranks 7 on the Mohs hardness scale, making it resistant to abrasion and ideal for heavy-duty industrial processes.

- Physical Properties: The mineral exhibits high compressive strength and low porosity, which contribute to its longevity under mechanical stress. Its natural color ranges from transparent to milky white, although trace impurities can produce shades of pink, purple, or gray.

- Chemical Stability: Quartz is chemically inert in most environments, resisting acids, bases, and weathering. This stability ensures that crushed quartz will not degrade or contaminate surrounding materials, making it a reliable component in concrete, glass, and ceramics.

- Crushed Products: When processed through a quartz rock crusher, the raw mineral is reduced to various graded aggregates and fine powders. Coarse fractions (e.g., 3 /8″ to ¾″) are ideal for foundational gravel and drainage layers, while medium grades (1–4 mm) serve as filler in asphalt and cement mixes. Ultrafine quartz powder (< 75 μm) finds use in high-precision applications such as electronic components, polishing agents, and specialty coatings.

Utilizing crushed quartz reduces reliance on virgin materials and minimizes quarry waste, contributing to more sustainable construction and manufacturing practices.

Quartz Crusher Equipment Composition

A modern quartz crushing and processing line consists of several key stages—each employing specialized equipment to ensure efficient, high-quality output. Below is a clear, step-by-step overview of the typical machinery used in a complete quartz crusher setup:

Vibrating Feeder

The vibrating feeder serves as the bridge between raw material delivery and primary crushing. By gently shaking and moving the quartz rock along a sloped, grizzly or pan feeder tray, this piece of equipment ensures a consistent, controlled feed rate into the primary crusher. Adjustable vibration frequency and amplitude allow operators to regulate flow, prevent feed surges, and remove fine debris before crushing begins.

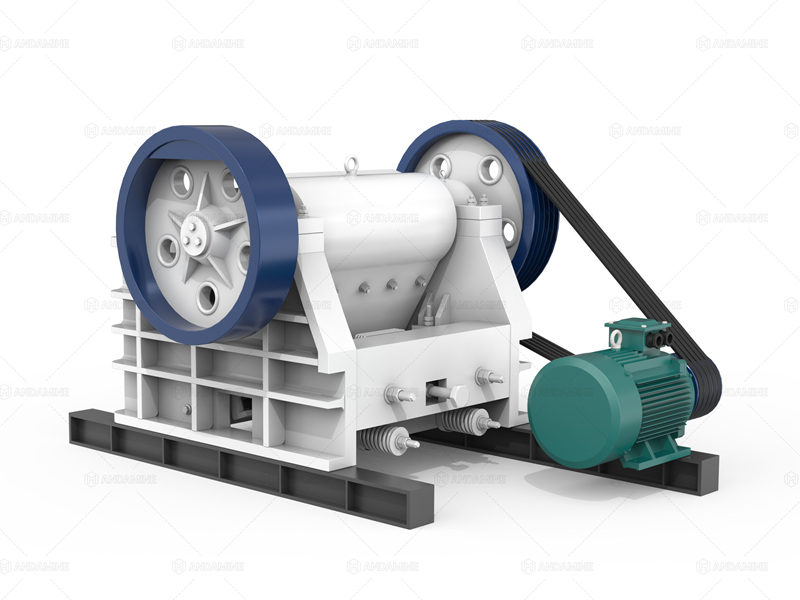

Primary Crushing Stage

In the primary crushing stage, a single or double toggle jaw crusher is typically employed to break large quartz rocks into smaller, more manageable pieces. The jaw crusher uses compressive force, as the movable jaw plate presses rock against the fixed jaw. Robust bearings, reinforced liners, and hydraulic overload protection safeguard the machine when encountering uncrushable objects, ensuring continuous operation and minimal downtime.

Secondary Crushing Stage

After initial reduction, quartz fragments proceed to secondary crushing for further size refinement. Two common options are cone crushers and impact crushers:

- Cone Crusher: Uses a rotating mantle within a stationary bowl to crush material through compressive action, producing cubical particles and high throughput.

- Impact Crusher: Accelerates quartz pieces against a series of blow bars and impact plates, shattering them into finer, angular fragments ideal for certain aggregate applications.

The choice between cone and impact crushers depends on desired particle shape, hardness of the quartz, and production capacity requirements.

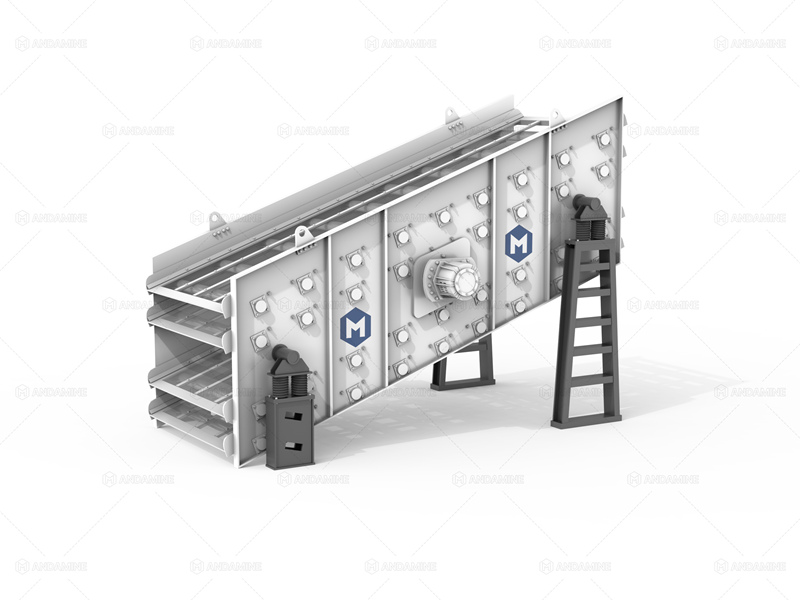

Screening Process

Once crushed to near specification sizes, the quartz material passes over vibrating screens with multiple deck configurations. Each deck is fitted with mesh screens of varying aperture sizes to separate finished aggregates into distinct size fractions (for example, 5–10 mm, 10–20 mm, and 20–40 mm). Oversized particles are returned to the secondary crusher in a closed-circuit loop, while undersized material moves forward to the sand washing stage or to final stockpiles.

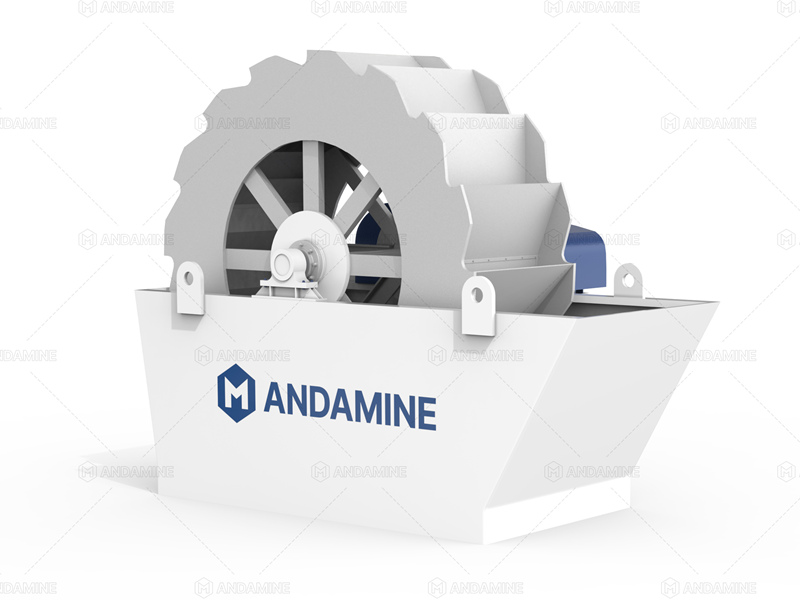

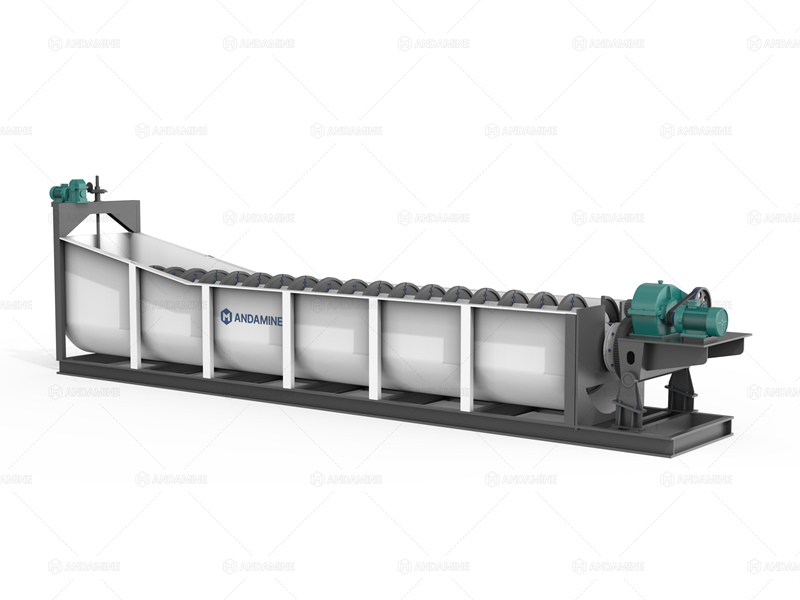

Sand Washing Process

To remove clays, silts, and fine impurities from the smallest quartz fractions, a sand washing unit is employed. Two prevalent types include bucket sand washing machine and spiral sand washers—which lift and roll quartz sand within a spiral trough, allowing fines to wash away. Clean water is recycled through settling tanks and hydrocyclones to maximize efficiency and reduce environmental impact.

By combining these six essential steps—material acquisition, vibrating feeding, primary crushing, secondary crushing, screening, and sand washing—quartz processing lines ensure consistent aggregate quality and optimal performance for downstream applications in construction, glass manufacturing, and beyond.

Equipment Selection and Configuration

When planning a quartz crushing solution, it’s essential to balance your project’s technical requirements with practical constraints. Below is a structured guide to help you—and your customers—choose and configure the right equipment, whether you need a mobile station like our four-in-one or three-in-one mobile crusher plant models, or a more traditional fixed plant.

Mobile Quartz Crushing Plants

Ideal For: Sites with limited space, frequent relocation, or phased construction projects.

Integrated Workflow

- Our four-in-one mobile crusher combines feeding, primary and secondary crushing, screening, and sand washing in a single chassis. This consolidates the entire process, reducing material handling and truck haulage between stages.

- The three-in-one mobile crusher similarly merges feeding, crushing, and screening, but emphasizes heavy-duty impact crushing for more abrasive quartz applications.

Key Features to Leverage

| Tri-axle Chassis & Ski-Plate Supports | Rapid set-up, stable operation on uneven or soft ground, and easy towing between sites. |

| Integrated Control & IoT Monitoring | One-click start via PLC touchscreen or buttons, plus remote diagnostics over 2G/3G/4G (or Wi-Fi/wired) to track motor loads, vibration, and maintenance alerts. |

| Modular Secondary Crushing | Swap in a cone crusher, impact crusher, or fine jaw crusher without rebuilding the frame—ideal if your product specs may change. |

| Low-Maintenance Design | ROSTA elastic mounts and side-plate vibrator motors reduce irregular vibration and extend service intervals to 1,500–2,000 hours. |

| Self-Dumping Magnetic Separator | Protects cones from tramp metal and prevents costly breakdowns. |

Fixed Quartz Crushing Plants

Ideal For: Large, long-term operations where steady, high-volume output justifies permanent installation.

Core Components

Vibrating Feeder & Hopper: Sized for expected feed rate; grizzly section removes fines and helps protect the primary crusher.

Primary Crusher (Jaw): Selected based on maximum feed size, desired throughput, and material hardness. Jaw crushers excel at handling large, abrasive blocks.

Secondary & Tertiary Crushers (Cone, Impact, VSI):

- Cone Crushers: Best for consistent, cubical aggregates in high-capacity plants.

- Impact Crushers / VSI: Offer better shape control and finer gradations, especially for decorative quartz sand(need to use VSI crusher).

- Vibrating Screens: Multi-deck screens separate material into precise size fractions; screen mesh apertures and deck angles are chosen to optimize screening efficiency.

Sand Washing & Dewatering Units: Bucket washers or spiral washers eliminate fines and clays, with water recycling circuits sized to local environmental regulations.

Parameter Considerations

| Throughput Capacity | Match crusher sizes and number of parallel units to your target tph (e.g., 500 tph primary, 300 tph secondary). |

| Feed & Product Size Ranges | Ensure feed opening, crusher liners, and screen mesh all align to deliver the required output gradation (e.g., 5–10 mm, 10–20 mm). |

| Power Supply & Energy Efficiency | Verify motor ratings, voltage compatibility, and look for energy-saving drives or variable frequency drives (VFDs). |

| Footprint & Civil Works | Plan for equipment foundations, access roads, and stormwater controls—especially important for VSI and washing units. |

| Dust & Noise Controls | Include dust collectors, fog sprays, and acoustic enclosures to comply with local regulations and protect worker health. |

01When to Choose Mobile

- You need to move the plant between different pits or job sites.

- Space is constrained and you wish to avoid extensive civil works.

- Your project timeline demands fast deployment and flexible production scales (100–400 tph typical).

02When to Choose Fixed

- You need continuous high-volume production (500 tph+).

- Site layout is stable, and you have budget for civil infrastructure.

- Product specifications are consistent over the project’s life.

By understanding both mobile and fixed crushing options—and how our four-in-one and three-in-one mobile stations fit into that spectrum—customers can select a quartz crushing machine configuration that aligns with their site constraints, production targets, and long-term flexibility needs. Whether you prioritize rapid deployment or maximum throughput, these guidelines will help ensure your investment delivers consistent, high-quality quartz aggregates.

Industries and Application Scenarios for Quartz Crushers

Quartz crushers serve many sectors by turning raw quartz into graded aggregates and powders. Below are the primary industry applications:

Mining and Extraction

Construction Materials

Glass Manufacturing

Semiconductor and Photovoltaics

Metallurgy

Chemicals, Ceramics, Paints and Coatings

Water Filtration and Environmental

Emerging Technologies

These concise applications illustrate the versatility of quartz crushers today and their expanding role in tomorrow’s advanced industries.

How to Improve ROI with Your Quartz Crusher

ROI, or Return on Investment, compares the net profit generated by a machine to its total cost. For a quartz crusher, ROI reflects how efficiently the equipment turns raw material into revenue while controlling purchase, installation, operation, and maintenance expenses.

Choosing a mobile crushing station cuts civil works expenses since the unit arrives pre-assembled. Without the need for extensive foundations, conveyors, or permanent utilities, you can begin production faster and avoid high upfront infrastructure investments.

Processing quartz onsite eliminates the fuel and labor costs of hauling raw rock to a distant plant and bringing crushed material back. By crushing at the quarry face, you streamline logistics and can reduce overall operating expenses by up to one-third compared to fixed installations. Mobile crushers maintain production continuity by moving alongside raw material sources. This flexibility minimizes idle time between excavation and crushing.

Equipping your crusher with sensors and IoT systems allows real-time tracking of vibration, temperature, and motor load. Predictive analytics use this data to schedule maintenance before failures occur, reducing unplanned downtime by nearly thirty percent and keeping the plant running at peak performance.

Modern crusher designs feature energy-efficient motors and variable frequency drives that lower power consumption. Advanced vibration mounts reduce mechanical stress, allowing maintenance intervals to stretch to 1,500–2,000 hours. These improvements cut both fuel and parts costs over the equipment’s lifetime.

Maintaining the correct feed size prevents machine overload and increases throughput. Ensuring smooth primary crushing cycles reduces the workload on secondary crushers and minimizes the need for material reprocessing, thereby saving time and energy.

A modular secondary crushing system lets you switch between producing coarse aggregate, fine sand, and specialty quartz powders as market demand changes. By offering multiple product grades, you can enter new markets and increase per-ton revenue.

If your quarry output does not fully utilize your crusher, provide portable crushing services to nearby projects. The mobility and rapid deployment of your unit make contract crushing a lucrative way to fill idle time and generate additional income.

How to Choose the Right Manufacturer

Selecting from many quartz crusher manufacturers is a critical step in ensuring long-term value from your quartz crusher investment. When evaluating suppliers, consider the following key strengths:

- Proven Track Record: Our company is recognized as a strategic partner of Fortune Global 500 companies, demonstrating both capacity and reliability at the highest level of industrial applications.

- Product Sophistication: Our flagship four-in-one and three-in-one mobile crushing solutions showcase advanced features—integrated control and IoT monitoring systems, modular design, and low-maintenance construction—engineered for efficiency, uptime, and flexibility.

- Comprehensive Support: We support every customer with full-service offerings—from consultation and turnkey solutions to post-sale training, spare parts, and troubleshooting—ensuring smooth installation, operation, and performance optimization.

Choosing ANDAMINE means working with a partner who delivers not just high-quality quartz crushers, but comprehensive industry expertise and unwavering support.

Investing in the right quartz crusher system is about balancing technical capability, operational efficiency, and market adaptability. With the right machinery and partner in place, your quartz processing venture becomes a robust, future-ready asset.