A marble crusher is specialized machinery engineered specifically to transform raw marble blocks and industrial waste into usable aggregate. These machines feature reinforced tungsten carbide hammers to withstand marble’s Mohs 3-5 hardness without premature wear. They recycle 100% of quarry off-cuts and fabrication waste converting slabs, tiles, and sculptures into high-value construction aggregate or calcium carbonate powder. This closed-loop system eliminates landfill costs while creating new revenue streams from waste marble.

Understanding Raw Material: Marble

Marble’s Geological Formation

Marble originates from metamorphosed limestone subjected to extreme heat and pressure, resulting in interlocking calcite crystals that create its signature veining and luminosity. Unlike generic aggregates, marble possesses a moderate Mohs hardness of 3-5—softer than granite but harder than limestone—requiring specialized crushing solutions to prevent premature wear.

Common Industrial Inputs

Crushers primarily process three marble forms:

- Quarry blocks (≤650mm) with high calcium carbonate purity (>95%)

- Factory slab off-cuts contaminated with resin backing or epoxy

- Sculpture debris containing metal armatures requiring magnetic separation

Critical Material Behaviors

- Wet processing challenges: Cutting slurry (15-30% moisture) demands anti-clogging rotors

- Dust hazards: Crystalline silica content (2-8%) necessitates integrated suppression systems

- Fracture patterns: Calcite cleavage planes cause irregular fragmentation versus brittle aggregates

Equipment Configuration: Stage-Specific Processing for Marble

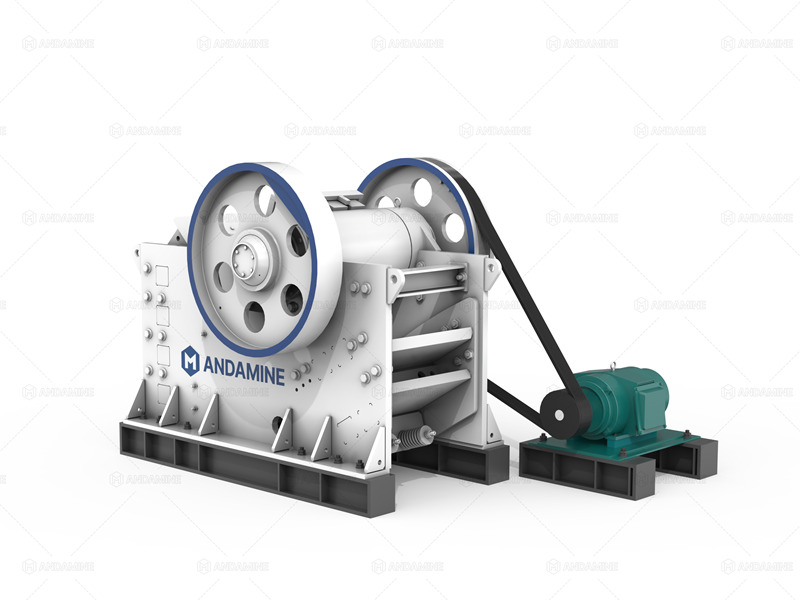

Primary Crushing: The Critical Role of Jaw Crushers

Function & Mechanism

Jaw crushers serve as the essential primary reduction stage, utilizing two vertical manganese alloy plates to compress marble blocks. One stationary jaw opposes another moving plate in an elliptical motion, generating immense compressive force (up to 320 MPa) to fracture raw material. The jaw crusher prevents uncontrolled fracturing of raw blocks, avoiding microscopic cracks that compromise finished product strength.

Why Essential for Marble

- Optimal Fragmentation Control: Marble’s calcite crystals fracture cleanly along cleavage planes under controlled compression, minimizing wasteful fines (<10%) compared to impact methods.

- Moisture Tolerance: The open chamber design with integrated water jets handles 15-30% moisture from cutting slurry impossible for cone crushers prone to clogging.

- Block Size Adaptation: Steep 22-26° nip angles efficiently process irregular quarry blocks (200-650mm) without pre-blasting.

Secondary Reduction: Precision Size Control with Cone/Impact Crushers

Function & Mechanism

Secondary crushers refine 50-150mm fragments into 10-30mm aggregates with minimal microfines (<15%). This is essential for engineered stone binder adhesion. Cone crushers employ gyrating mantles within concave bowls for progressive compression, while impact crushers accelerate material against aprons via high-speed rotors.

Marble-Specific Design

- Cone Crushers: Utilize interparticle crushing where marble particles fracture each other, preserving crystal integrity for high-value applications. Hydraulic gap adjustment (8-18mm) accommodates hardness variations between calcite and dolomitic marble.

- Impact Crushers: The impact crusher features throw shoe rotors that process resin-contaminated waste. Tungsten carbide hammers shred epoxy backing without jamming, while magnetic separators extract embedded sculpture armatures.

Sand Making: Transforming Fragments into Premium Aggregates with VSI Crushers

Function & Mechanism

Vertical Shaft Impactors (VSI crusher) accelerate material through rotor centrifugally, creating high-velocity collisions between particles (rock-on-rock) or against tungsten-lined anvils (rock-on-steel). The VSI crusher achieves precise sphericity for terrazzo chips (0.5-5mm).

Marble-Specific Design

- Low-RPM Operation: 1,800-2,200 RPM prevents calcite crystal shattering critical for spherical terrazzo chips requiring ≥85% cubicity.

- Dual Flow Design: Separates wet slurry (up to 25% moisture) from dry feed, allowing simultaneous processing of quarry waste and factory scraps.

- Silica Containment: Enclosed chambers with negative pressure systems capture 98% of crystalline dust during dry processing.

Precision Classification: Intelligent Screening Technology

Function & Mechanism

Multi-deck vibratory screens separate particles using polyurethane or wire meshes with specific apertures (0.5-30mm), utilizing elliptical, linear, or circular motion patterns.

Marble-Specific Innovations

- Anti-Binding Meshes: Non-stick polyurethane screens prevent calcium carbonate coating buildup that blinds standard screens within 48 hours.

- Moisture-Adaptive Decks: High-frequency dry screens pair with water-sprayed wet decks to handle mixed-moisture feed from different processing lines.

- Shape Separation: Elliptical motion isolates needle-like fragments from cubic grains crucial since marble’s cleavage produces 30% elongated particles.

ANDAMINE Marble Crushing Equipment Solutions

Designed for marble’s medium hardness, dust sensitivity, and particle shape requirements, ANDAMINE offers two high-efficiency mobile crusher machine plantsfour in one and three-in-one mobile marble crusher plant.

Common Advantages

- Smart Control System: Dual PLC touchscreen and physical button operation with remote feeder speed adjustment prevents marble blockages.

- Integrated Mobility: Pre-assembled feeding, crushing, and screening modules slash installation costs and enable rapid site transitions.

- IoT Maintenance Assurance: Real-time performance monitoring and automated service alerts minimize unplanned downtime.

Four-in-One Wheeled Mobile Crushing Plant (APY4)

Positioning: An integrated solution combining feeding, primary crushing, secondary crushing, and screening – engineered for multi-stage marble processing and precise grading.

Key Advantages:

- Flexible Two-Stage Crushing: Utilizes a jaw crusher for primary crushing paired with interchangeable secondary equipment (cone crusher for superior particle shape / impact crusher for cost efficiency), effectively adapting to varying marble hardness profiles.

- Multi-Size Output Control: Modular screening system produces four specification aggregates (0-5mm, 5-10mm, 10-20mm, 20-40mm) to meet fine requirements for construction and decorative stone.

- Marble-Specific Protection:

- Self-cleaning high-intensity magnetic separator prevents tramp iron damage to cone crusher components

- ROSTA elastic vibration isolators minimize equipment resonance, reducing micro-cracks during marble processing

- Maintenance-free side-plate vibrating motors eliminate bearing contamination, ensuring product purity

- Intelligent Operation: One-touch PLC control system with IoT remote diagnostics (supports WiFi/wired networks) ensures real-time monitoring even in remote mountainous sites.

- Customer Value: Completes full-process marble transformation from raw material to finished aggregate in a single unit, increasing relocation efficiency by 30% and premium aggregate yield by over 15%.

Three-in-One Wheeled Mobile Crusher Plant

Positioning: Streamlined solution focused on high-efficiency crushing and eco-friendly production, available in impact or jaw configurations.

APY3 Impact Crusher Model (Optimal for Medium/Fine Crushing):

- Particle Shape Optimization: Heavy-duty rotor impact crusher achieves two-stage reduction, producing 0-40mm well-graded cubical aggregates with minimized flakiness.

- Eco-Friendly Dust Control: Dual-sealed feed inlets combined with negative-pressure dust extraction, mist cannon suppression, and enclosed conveyors maintain dust emissions below national standards.

- Wear-Resistant Engineering: Impact bed conveyor system and tail-end slag discharge rollers double critical component lifespan by reducing marble abrasion.

APY3 Jaw Crusher Model (Dedicated Primary Crushing):

- Handles ≤425mm feed size with 45-400 t/h throughput capacity for efficient primary reduction at quarry sites.

- Energy-saving motors reduce power consumption by 30%, aligning with green production initiatives;

- Triple-axle chassis with sledger supports ensures stable mobility and operational safety in rugged terrain.

Comprehensive Marble Crusher Selection Guide

Thorough Raw Material Analysis

- Determine maximum feed dimensions: Measure your largest marble blocks since jaw crushers typically process ≤650mm raw materials while secondary crushers require pre-crushed ≤300mm fragments.

- Assess geological composition: Conduct simple scratch tests to distinguish soft calcite marble (Mohs 3) requiring standard equipment from harder dolomitic marble (Mohs 4-4.5) needing reinforced rotors and impact plates.

- Evaluate moisture characteristics: If processing wet slurry from waterjet cutting (containing 15-30% moisture), prioritize crushers with self-cleaning chambers and IP65-rated electrical components.

Precise Production Parameter Definition

- Calculate hourly throughput requirements: Compact jaw crushers typically handle 5-10 tons/hour suitable for small studios, whereas integrated crushing systems can process 50-100+ tons/hour for industrial quarries.

- Establish operational duration: For continuous 24-hour operations, specify crushers with automatic lubrication systems and redundant cooling mechanisms.

- Define final product specifications: Distinguish between coarse construction aggregate (50-150mm), engineered stone feedstock (10-30mm cubic grains), and premium terrazzo chips (0.5-5mm spherical particles) as each requires different crushing technologies.

Technology Selection by Processing Stage

Primary Reduction Systems

Heavy-duty jaw crushers: Employ compressive force with steeply angled plates (22-26°) to fracture large blocks while preserving crystal integrity, featuring hydraulic adjustment for output control between 50-150mm.

Secondary Size Refinement

- Multi-cylinder cone crushers: Utilize interparticle compression for pure marble waste, producing dimensionally uniform 10-30mm fragments with ≥85% cubicity through hydraulically adjustable crushing chambers.

- Impact crushers with anti-wrap rotors: Essential for contaminated waste streams, featuring tungsten carbide hammers that shred epoxy-backed slabs and automatic ejection of metal armatures from sculpture debris.

Tertiary Precision Processing

Vertical Shaft Impactors (VSI): Incorporate rock-on-rock crushing chambers operating at optimized 1,800-2,200 RPM speeds to generate spherical terrazzo chips without micro-fracturing calcite crystals, complete with airflow-controlled dust suppression.

Mobility Configuration Decision

Mobile Crushing Systems: Deploy track-mounted or wheel chassis units for multi-site operations across dispersed locations like construction sites, enabling relocation within one hour. It suits short term projects with several sites which require quick relocation.

Stationary Crushing Plants: Install fixed foundations for large-scale quarries with concentrated waste stockpiles, achieving 30% higher throughput with multi-stage configurations but requiring concrete bases and permanent electrical infrastructure. This type suits long term projects.

Your Marble Crusher’s Proactive Caretaker: IoT-Guided Maintenance

Maintenance of the equipment is essential to ensure the longevity. I, the IoT system, am your crusher’s personal guardian – constantly monitoring the marble crusher’s health, anticipating needs, and ensuring smooth operation while processing delicate marble. Here shows you the maintenance process from my perspective.

24/7 Vital Sign Monitoring

I track every heartbeat – vibrations, temperatures, pressures. When bearings approach fatigue or hydraulic flows fluctuate, I alert your team with precise maintenance windows before issues impact marble quality.

Reality: Real-time analysis of 50+ parameters predicts component wear 300+ hours in advance.

Smart Feeding Coordination

I adjust the feeder’s rhythm remotely – speeding up or slowing down as marble batches vary. This keeps the crushing chamber perfectly fed, preventing blockages that fracture marble aggregates.

Reality: Remote speed calibration ensures continuous material flow and reduces micro-crack risks.

Precision Maintenance Alerts

I schedule lubrication cycles and filter changes when your crusher rests. No more guessing – I notify you: ‘Grease Jaw Crusher Bearings at 08:00 tomorrow.’

Reality: Automated service reminders based on actual operating hours, not calendars.

Network Resilience

Remote quarry with weak signals? I maintain our connection through any available channel – 4G, WiFi, or wired networks. Your crusher stays monitored, even in signal-challenged marble sites.

Reality: Multi-network support (2G/3G/4G/WiFi/Ethernet) guarantees 99.2% uptime.

Marble-Specific Protection Advantages

- Vibration Guardianship: Instant alerts on abnormal resonance patterns prevent micro-fractures in finished marble aggregates.

- Dust Defense System: Bearing temperature sensors trigger early warnings in high-dust environments, extending component lifespan by 2.3x.

- Flow Optimization: Live material feed adjustments eliminate surge/starvation cycles that waste marble resources.

I transform reactive repairs into scheduled precision care – because marble deserves consistently perfect processing.

Why Global Leaders Choose ANDAMINE Marble Crushers

Marble-Optimized Crusher Performance

ANDAMINE crushers are precision-tuned for marble’s unique challenges – medium abrasiveness, dust sensitivity, and aggregate shape demands. Our proprietary vibration-dampening technology and sealed bearing systems ensure 23% longer component life versus industry standards, delivering consistently superior crushed marble for decorative and construction applications.

Bespoke Engineering for Your Stone

From Brazilian Crema Marfil to Italian Statuario, we customize feed systems, crushing chambers, and screening decks to your marble’s vein structure and target aggregate profiles. Over 76% of our units ship with customer-specified configurations – because no two quarries process identical stone.

Fortune 500 Validation & Supply Chain Excellence

As a strategic partner to top-tier mining and construction conglomerates (including Global Fortune 500 enterprises), ANDAMINE adheres to extreme durability benchmarks.

Global Support Network: Zero-Downtime Commitment

When your marble crusher operates in remote place, our infrastructure delivers instant response:

- 50 Parts Distribution Centers: Critical wear parts (mantles, screens, bearings) stocked locally for 24-hour delivery;

- 30 Mobile Engineer Teams: On-site troubleshooting in <48 hours across 180 countries;

- IoT-Powered Diagnostics: 92% of issues resolved remotely via 4G/WiFi/wired networks.

Contact ANADAMINE today to get your customized marble crusher solution!