A granite crusher is designed specifically to break down granite, one of the hardest natural rocks, into smaller, usable pieces for construction and industrial applications. The crushers use mechanical force—such as compression, impact, or abrasion—to crush granite into different sizes suitable for aggregates, road base, concrete, and asphalt.

In this article, we’ll explore what a granite crusher is, the types available, and which applications it’s best suited for. Whether you’re in construction or just curious, this guide will break it down for you.

What Is Granite and Its Characteristics

Granite is a coarse-grained igneous rock formed by the slow crystallization of magma deep within the Earth’s crust. This process results in a rock composed predominantly of quartz, feldspar, and mica.

Key Characteristics:

- Hardness: Granite is exceptionally hard due to its interlocking mineral crystals. On the Mohs scale of mineral hardness, granite typically rates around 6 to 7. This high hardness gives granite its lasting durability but also makes it challenging to break down.

- Density: Granite is also a dense material, usually ranging from 2.63 to 2.75 g/cm³. Its density contributes to its strength and stability, which are critical for construction applications.

- Abrasion Resistance: The compact structure of granite provides excellent abrasion resistance, making it ideal for high-wear environments.

- Aesthetic Appeal: Granite’s natural patterns and variety of colors contribute to its popularity in both structural and decorative applications.

Why Granite Needs Specialized Equipment for Crushing

Extremely Hard Material

Granite is one of the hardest natural stones, ranking high on the Mohs hardness scale. Its dense and crystalline structure makes it resistant to abrasion and wear. Standard crushing machines may not withstand the stress of processing granite without excessive wear and tear.

High Compressive Strength

Granite’s high compressive strength requires heavy-duty crushers with strong, reinforced components. Specialized equipment like jaw crushers, cone crushers, and impact crushers designed for hard rock are necessary to break down granite efficiently and safely.

Efficient Reduction and Shaping

To produce high-quality aggregates, the equipment must not only crush granite but also shape it according to specific requirements. Specialized machines allow for precise control over the final product size and shape, which is essential for construction and asphalt applications.

Protection Against Equipment Damage

Because of granite’s hardness and potential to contain sharp edges, crushing it without the right equipment can lead to frequent breakdowns and maintenance. Specialized crushers come equipped with wear-resistant parts, hydraulic protection systems, and automated controls to handle the load safely.

Energy and Cost Efficiency

Specialized granite crushers are designed for energy efficiency and longevity, reducing operational costs over time. Using general-purpose machines would lead to higher fuel consumption, quicker component wear, and more downtime.

Which Type of Crusher Is Suitable For Processing Granite?

Granite is a hard, dense, and abrasive material, so it requires crushers that can handle high compressive strength and deliver durable performance. The granite crushers can be broadly classified into four main categories based on their crushing mechanism and application: jaw Crushers, cone Crushers, impact Crushers, and mobile granite crushers. In the sections below, we will examine each type in detail.

Jaw Crusher – For Primary Granite Crushing

Jaw crushers operate by using two plates—one stationary and one that moves back and forth—to crush the rock between them. The raw granite is fed into the top of the crusher, and as the moving jaw advances, the rock is compressed against the stationary jaw. The material is crushed until it reaches the desired size and is then discharged. Our jaw crushers can transform raw rock (up to 1000mm in size) into uniform outputs (15–300mm) at staggering capacities (50–800T/H).

Ordinary type – APJ-E series Jaw Crusher

European type – APJ-V series Jaw Crusher

Fine crush type – APJ-X series Jaw Crusher

Advantages:

- High Production Efficiency: The deep crushing chamber design eliminates dead zones, improving feeding capacity and overall output. This boosts production efficiency while reducing energy consumption.

- Excellent Wear Resistance: All key components are made from high-quality materials, greatly enhancing their pressure and wear resistance. The movable jaw is made from cast steel, and the eccentric shaft is forged, improving overall durability and reliability.

- Adjustable Discharge for Flexibility: The discharge port is equipped with a shim adjustment system, which is not only reliable and easy to operate but also allows for flexible control over the final product size.

- Easy Maintenance: The jaw crusher is simple to operate and easy to maintain. Its design helps reduce downtime for maintenance, ensuring continuous and efficient operation.

Best Applications:

- Initial reduction of large granite blocks in quarrying.

- Pre-crushing stage in multi-stage crushing processes.

- Situations where rugged durability is more critical than product fineness.

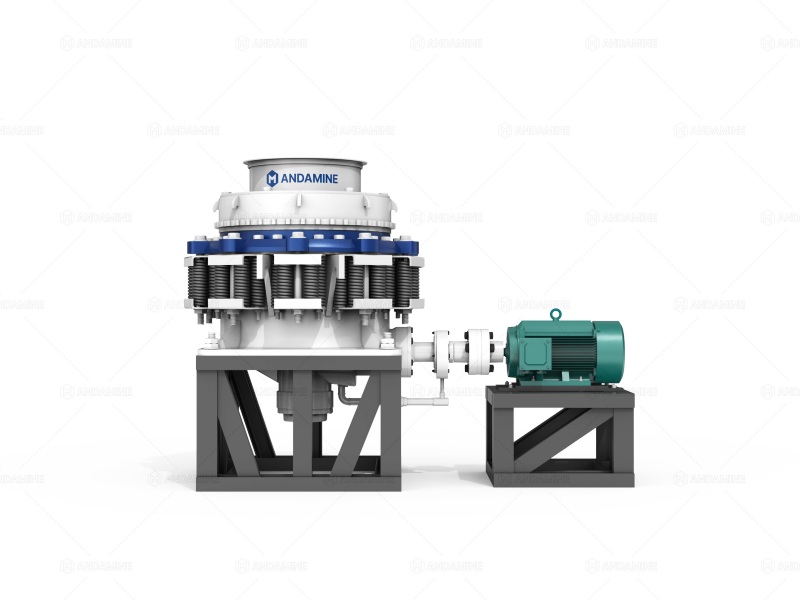

Cone Crusher – For Secondary and Fine Granite Crushing

Cone crushers reduce rock by using compressive force. The machine consists of a concave surface and an eccentrically gyrating cone. As the cone rotates within the concave, the granite is squeezed between these surfaces until it breaks into smaller fragments.

Our cone crushers feature a feeding size range of 65–300 mm, with adjustable output sizes of 5–10 mm and 10–40 mm, and offer a wide capacity range from 20 to 1000 tons per hour, making them suitable for various crushing applications.

APC-D Single Cylinder Hydraulic Type Cone Crusher

APC-M Multi-cylinder Hydraulic Type Cone Crusher

APC-Y Spring Type Cone Crusher Machine

APC-C Compound Type Cone Crushing Machine

Key Characteristics:

- Secondary or Tertiary Crushing: Cone crushers are typically used after the jaw crusher as secondary or tertiary crushers.

- High Reduction Ratios: They are capable of producing finer and more uniform aggregates.

- Efficient and High Throughput: Ideal for high production volumes with controlled particle size distribution.

Best Applications:

- Production of aggregates for high-strength concrete.

- Secondary and tertiary crushing in large mining or quarry operations.

- Projects where precise particle size control is needed.

Impact Crusher – For Shaping and Final Stage

Impact crushers use impact force to break down rock. The material is fed into the crusher where it is struck by hammers or blow bars attached to a rotor. The high-speed impact causes the granite to shatter. The finished product is in a cubic shape, free from tension cracks, with a well-formed grain shape that meets various graded standards for sand and gravel aggregates.

Our impact crushers support a maximum feeding size of ≤500 mm, deliver output sizes ranging from 5 to 200 mm, and offer a capacity of 40 to 400 tons per hour, making them ideal for medium to large-scale crushing operations.

APF-V Series Impact Crusher

APF-H European series Impact Crusher Machine

Advantages:

- Refined Design: The rotor and crushing chamber are precisely engineered, with optimized speed and power matching to meet various application requirements.

- High-Strength Frame: The use of a high-strength frame structure enhances connection integrity while remaining lightweight and compact, making installation, maintenance, and transportation easier.

- Safety Locking Devices: Equipped with multiple safety locking mechanisms, the crusher ensures higher operational safety while reducing labor intensity.

- Boat-Shaped Blow Bar: Features a reliable locking mechanism that provides excellent impact and wear resistance. It maintains consistent discharge size and allows for both vertical and horizontal blow bar replacement to suit different site conditions.

- Modular Design: Most wear parts are interchangeable due to the modular structure, which reduces wear part consumption, extends replacement cycles, lowers spare parts inventory, and ultimately saves costs.

Best Applications:

- Medium hardness granite crushing for decorative stone and road base material.

- Secondary crushing where a well-shaped aggregate is required.

- Situations where adjustability of particle size is necessary.

Mobile Granite Crusher Plant – For On-Site Flexibility

Mobile granite crusher plants combine the features of fixed crushing equipment with the flexibility of mobility. These machines are mounted on a wheeled or tracked chassis and are capable of moving from one site to another. They incorporate crushing, screening, and conveying operations in one integrated and mobile unit.

APY wheeled mobile crusher plant

APYL tracked mobile crushing plant

Key Characteristics:

- Flexibility and Mobility: Easily transported to and set up at different sites.

- Integrated Systems: Often include additional modules such as screening and conveyor belts for a complete crushing solution.

- Rapid Deployment: The mobile crusher plant can be quickly installed and disassembled, saving time in projects where on-site production is required.

Best Applications:

- Road construction and urban infrastructure where mobility is key.

- Projects in remote areas lacking permanent crushing facilities.

- Short-term, high-demand projects where rapid setup and flexibility are vital.

What Is Crushed Granite Used For?

Crushed granite is a versatile material, widely used in various construction and infrastructure projects due to its durability and aesthetic properties. Here are some common applications:

Construction Applications

Crushed granite is widely used as a strong and durable aggregate in concrete and asphalt mixes, making it ideal for roads, bridges, and building foundations. Its strength and resistance to wear also make it suitable as a base material for sidewalks, patios, and driveways. Additionally, it is used as railroad ballast to stabilize and support train tracks.

Landscaping and Decorative Uses

In landscaping, crushed granite serves both functional and aesthetic purposes. It’s commonly used as decorative stone in garden paths, borders, and retaining walls due to its natural color and texture. As a mulch or ground cover, it helps conserve soil moisture, suppress weeds, and requires little maintenance. It’s also popular in hardscape designs like walkways and patios.

Drainage and Erosion Control

Thanks to its coarse and permeable nature, crushed granite is ideal for drainage solutions such as French drains and other water management systems. It also plays a role in erosion control, helping to stabilize slopes and prevent soil loss in vulnerable areas.

Industrial and Environmental Uses

Crushed granite is sometimes reused as recycled aggregate in construction, reducing the need for virgin materials. In landfills, it can be used as a cover material to minimize dust and stabilize the site, contributing to more sustainable waste management practices.

Granite Processing Solutions – Mobile Crusher Plant Projects

As an experienced and reliable crusher plant supplier, we offer a wide range of granite crusher plants tailored to meet diverse project requirements. To help you make an informed decision, you can explore the project cases below featuring our granite crushing plants as reference.

200T/H Mobile Granite Crusher Plant In Malaysia

- Crusher Type: Crawler Type

- Raw Material: Granite

- Finished Product: 80-100mm

- Application: Using crushed granite for road paving.

150T/H Mobile Granite Crushing Plant In Honduras

- Crusher Type: Wheel Type

- Raw Material: Granite

- Finished Product: 5-10, 10-20mm

- Application: Crushing granite for industrial applications.

Performance Parameters of a Granite Crusher

Crushing Capacity (t/h)

Crushing capacity refers to the amount of granite the crusher can process per hour. It varies depending on the model and type of crusher (jaw, cone, or impact), ranging from 50 tons/hour to over 1000 tons/hour for large-scale operations.

Feed Size (mm)

The maximum size of granite that the crusher can accept. For jaw crushers, feed size can go up to 1000 mm, while cone and impact crushers typically handle smaller input sizes around 300–500 mm.

Discharge Size (mm)

This is the size of the crushed granite output. Crushers offer adjustable settings to achieve desired output sizes, usually between 5 mm and 40 mm, depending on the application (e.g., road base, concrete aggregate).

Crushing Ratio

The ratio of the input size to the output size. A higher crushing ratio indicates more effective size reduction. Granite crushers typically offer a ratio between 3:1 and 10:1, depending on the crusher type.

Power Consumption (kW)

Indicates how much energy the crusher consumes during operation. Power requirements vary by machine size and type, usually ranging from 75 kW to 400 kW for heavy-duty granite crushers.

Wear Resistance

Since granite is a hard rock, crusher components like jaws, cones, and liners must be made of high manganese steel or alloyed materials for durability and longer service life.

Automation and Control Systems

Modern granite crusher machines often include hydraulic adjustment, automated overload protection, and real-time monitoring systems to ensure safety, efficiency, and easier operation.

Mobility (Optional)

Mobile granite crusher plants (tire or crawler type) offer the advantage of on-site crushing, reducing transport costs and making them ideal for construction sites and quarry operations.

Contact Us for Reliable Granite Crushers

Understanding what a granite crusher is and the different types available is essential for anyone involved in construction, mining, or material processing. It enables you to choose the most suitable equipment for your specific project requirements, ensuring efficient performance and high-quality results. Additionally, having this knowledge supports better cost control, maintenance planning, and overall productivity. If you’re interested in learning more about granite crushers or need help selecting the right solution for your project, feel free to contact us—we’re here to provide the ideal recommendation.