Unsure how to choose a mobile crushing plant that truly matches your site and material requirements? Choosing the wrong plant can lead to frequent downtime, inconsistent output, excessive wear, and rising operating costs—problems that can derail your project and shrink your profit margins. The right choice isn’t just about size or capacity. Factors like material hardness, site conditions, and equipment configuration determine daily performance and long-term costs. This guide breaks down 7 essential steps to help you make an informed decision, avoid costly mistakes, and ensure reliable output and maximum ROI.

Step 1: Assess Your Crushing Requirements

Before purchasing a mobile crusher plant, it’s essential to have a clear and detailed understanding of your project’s crushing requirements. This step lays the foundation for all subsequent decisions and ensures you avoid costly mistakes, underperformance, or operational inefficiencies.

Assessing crushing requirements involves understanding four key aspects: material characteristics, production capacity, desired final product specifications, and the intended use of the crushed material.

Material Characteristics

The type and properties of the material you plan to process are the most critical factors in determining your crushing requirements. Consider:

- Hardness: How tough is the material? Hard rocks like granite or basalt will stress equipment more than softer materials like limestone.

- Abrasiveness: Highly abrasive materials increase wear on crushing components and require robust handling strategies.

- Moisture Content: Wet or sticky materials can clog crushers and reduce efficiency.

- Impurities: Metal, debris, or recycled materials can interfere with operation and affect output quality.

Understanding material properties helps you define the necessary handling capacity, durability requirements, and preprocessing needs, ensuring the plant can operate efficiently without excessive downtime or maintenance.

Production Capacity Requirements

Define exactly how much material needs to be processed:

- Hourly or Daily Output: Tons per hour (TPH) or total project volume. Be realistic and account for peak demand periods.

- Project Scale: Small projects may only need a modest output, while large, continuous operations require higher capacities.

- Variability: Consider whether production will be consistent or fluctuate over time.

Setting a clear production target ensures that your crusher plant can meet project deadlines without underloading or overloading equipment.

Desired Final Product Size and Shape

The specifications of the end product determine the level of processing required:

- Particle Size Range: Coarse, medium, or fine. Different construction applications have specific size requirements.

- Particle Shape: Cubic, angular, or irregular. Certain applications, like asphalt or high-quality concrete, require more uniform, cubic particles.

- Consistency: Uniformity in size and shape is critical for quality and compliance with construction standards.

Clear product specifications prevent mismatches between production output and project requirements, reduce waste, and ensure the material meets quality standards.

Intended Use of the Crushed Material

Understanding the final application of your crushed material guides your operational planning:

- Road Base or Sub-Base: Requires coarse, well-graded materials.

- Concrete Aggregates: Need consistent size and shape for structural performance.

- Asphalt Aggregates: Fine, cubic particles are often required.

- Sand Production: Very fine material (0–5 mm) may need specialized processing.

- Recycling Applications: Demolition debris, concrete, or asphalt may contain metals or contaminants that affect processing.

Knowing the intended use ensures that your plant configuration, screening, and handling systems are compatible with project goals, maximizing product quality and compliance.

Step 2: Understand the Crusher Types for Mobile Plants

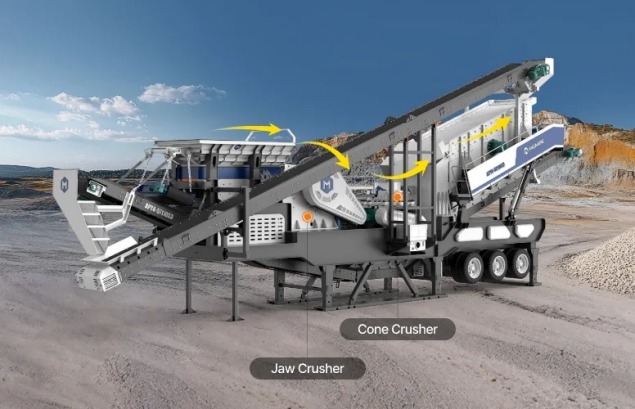

Choosing the right type of mobile crusher is essential to match your material properties, output needs, and application goals. Mobile crushing plants are typically equipped with one or more of the following crusher types — each designed for specific crushing tasks and material characteristics. Understanding how each works will help you make a better investment decision.

Jaw Crusher: Primary Crushing for Large and Hard Materials

A jaw crusher is ideal for the primary crushing stage, where large, hard materials like granite, basalt, and reinforced concrete need to be broken down into manageable sizes. The material is fed into a V-shaped chamber and crushed between a stationary and a moving jaw plate.

Capacity:20-1200t/h

Max Feeding Size:<680mm

Output Size:3-60mm

Pros:

Very robust and reliable for hard materials

Simple design with low maintenance

High feed capacity

Cons:

Output size is coarse and irregular

Not suitable for shaping or fine gradation

Bulkier compared to other crushers

Ideal For: Mining operations, hard stone quarries, and concrete recycling where large chunks need initial reduction.

Cone Crusher: Secondary/Tertiary Crushing-Finer Gradation

Cone crushers are commonly used for secondary or tertiary crushing, especially for hard and abrasive materials. Material is compressed between a rotating cone and a fixed outer shell, gradually breaking into smaller particles.

Capacity:50-1200t/h

Max Feeding Size:<350mm

Output Size:3-60mm

Pros:

Consistent and fine output size

Handles hard and abrasive rock well

Lower wear rate than impact crushers for hard material

Cons:

Higher initial investment

Slower processing for softer materials

Less effective on wet or sticky material

Ideal For: High-production quarries, mining sites, and applications requiring controlled particle size and high-quality aggregates.

Impact Crusher: For Soft to Medium Materials-Cubic Output

Impact crushers are used for secondary crushing and are excellent for medium-hard to soft materials like limestone, concrete, and asphalt. Material is thrown against impact plates and broken by repeated high-speed impacts.

Capacity:20-900t/h

Max Feeding Size:<700mm

Output Size:5-180mm

Pros:

Produces well-shaped, cubic aggregates

Good reduction ratio

Ideal for recycling applications

Cons:

High wear rate with abrasive materials

Less effective on very hard rocks

Requires more frequent maintenance

Ideal For: Road base material, recycled concrete, and aggregate production requiring good shape and uniform size.

VSI Crusher: Sand-Making and Shaping Capabilities

Vertical Shaft Impact Crushers, known as VSI crushers, are designed for sand production and aggregate shaping. Material is accelerated and thrown against a rock-lined wall or steel anvils, breaking into fine, cubical particles.

Capacity:60-480t/h

Max Feeding Size:30-55mm

Output Size:0-4.75mm

Pros:

Produces high-quality, well-shaped sand

Excellent for final product shaping

Great for asphalt and concrete aggregate specs

Cons:

Not suitable for primary crushing

Limited feed size capacity

High energy consumption for coarse materials

Ideal For: Manufactured sand production, shaping coarse aggregates, and improving overall material quality.

Quick Selection Guide: Match Your Material to the Right Crusher Type

| Material Characteristics | Recommended Crusher Type | Key Advantages | Typical Applications |

|---|---|---|---|

| Very hard, high abrasion (compressive strength >250 MPa) | Cone Crusher | Laminated crushing principle; reduced liner wear; consistent product gradation; excellent particle shape | Granite, basalt, river gravel, quartz |

| Medium to low hardness; high-quality aggregate required (e.g. commercial concrete) | Impact Crusher | High-speed impact crushing; superior cubical particle shape; well-graded aggregates; high-value end products | Limestone, calcite, recycled concrete |

| Any hardness; primary coarse crushing; large feed size; high throughput | Jaw Crusher | Robust structure; wide adaptability; large feed opening; reliable high-capacity primary crushing | All types of ore, demolition debris, large concrete blocks |

| Fine shaping required; sand production; strict particle shape and grading control | VSI Crusher (Vertical Shaft Impact Crusher) | Rock-on-rock or rock-on-metal crushing; excellent shaping effect; high-quality manufactured sand; controllable gradation | Manufactured sand, aggregate shaping, fine crushing stages, concrete & asphalt sand production |

Step 3: Consider Site Conditions and Mobility Needs

After understanding your crushing requirements and the types of mobile crushers, it’s essential to consider the conditions of your site and the mobility needs of the plant. Even the best crushing equipment can underperform if it’s not suitable for the terrain, space constraints, or environmental requirements. Key factors to evaluate include site terrain, space availability, environmental considerations, climate, and relocation frequency.

Terrain and Ground Conditions

Flat or Uneven Terrain:

- Mobile crushing plants on tracks (crawler type) are better for rough, uneven ground, slopes, or remote locations.

- Wheeled mobile plants are more suitable for flat, stable surfaces like urban construction sites or paved areas.

Soil Type and Stability:

- Soft or muddy soil may require ground reinforcement or stabilizers for heavy mobile plants.

- Rocky or abrasive surfaces may accelerate wear on undercarriages and tracks.

Why it matters: Matching the mobility type to terrain ensures safe, stable, and efficient operation, and avoids downtime caused by site accessibility issues.

Space and Layout Constraints

Available Working Area:

- Urban sites or renovation projects often have limited space for large mobile plants.

- Compact or modular designs may be required for tight job sites.

Material Flow and Staging:

- Ensure there’s sufficient space for stockpiles, conveyors, and vehicle movement.

- Plan for feeding, screening, and discharge areas without bottlenecks.

Why it matters: Proper space planning prevents operational delays, ensures safety, and maximizes throughput.

Environmental and Regulatory Considerations

Noise and Dust Restrictions:

- Some urban or sensitive areas have strict noise and dust emission limits.

- Consider plants with enclosed feeders, dust suppression, and low-noise engines.

Local Regulations:

- Check environmental permits, transport restrictions, and work-hour limitations.

Why it matters: Compliance avoids fines, project stoppages, and reputational risk.

Climate and Weather Conditions

Extreme Temperatures:

- High heat can negatively impact hydraulic systems and electronics, potentially causing failures or reduced performance.

- Cold environments may need preheating or antifreeze systems to ensure smooth operation and prevent damage.

Rain and Snow:

- Wet materials can easily clog crushers and screens, reducing efficiency and increasing maintenance requirements.

- Proper drainage systems and weather-resistant plant designs are essential to maintain reliable operation under wet conditions.

Why it matters: Climate-adapted equipment ensures reliable operation year-round and minimizes weather-related downtime.

Relocation Frequency and Mobility Needs

Frequent Site Changes:

- Crawler-mounted mobile plants allow rapid relocation over uneven terrain.

- Wheeled crusher plants are ideal for highway transport between projects.

Setup and Teardown Time:

- Consider plants with fast hydraulic folding conveyors, quick assembly, or plug-and-play components.

Why it matters: Efficient mobility reduces transport costs, labor requirements, and lost production time.

Tracked vs. Wheeled: Choosing the Right Undercarriage

|

|

|

|---|

| Site Conditions & Needs | Recommended Chassis | Why Choose This Type | Key Notes |

|---|---|---|---|

| Rough, uneven, or soft terrain (mountains, wetlands, mud, rocky ground) | Crawler (Tracked) | Excellent stability, can move on-site without extra transport, adapts to complex terrain | Higher upfront cost; slower road travel; long-distance moves may require a truck |

| Frequent site relocation, need on-site flexibility | Crawler (Tracked) | Quick relocation and setup, minimal groundwork needed | Ideal for multi-site projects; reduces downtime |

| Flat or semi-prepared site, occasional relocation, road transport | Wheeled | Road-legal, easy to tow between sites, cost-effective | Requires level ground and hydraulic legs for setup; limited off-road capability |

| Urban construction or projects with strict environmental limits (dust/noise) | Wheeled (with Hydraulic Legs) / Crawler + Dust Control | Fast setup, level adjustment, reduces dust, meets urban environmental requirements | Requires water/power supply for dust suppression; configuration can be added to either chassis |

| Long-term heavy-duty operation with obstacles | Crawler with Advanced Servo/Hydraulic Control | Stable, high load capacity, precise operation | Higher capital cost; skilled operators recommended |

Step 4: Evaluate Flexibility and Customization Options

Open-Circuit vs. Closed-Circuit Systems

- Open-Circuit Plants: Material passes through the crusher once, producing a single grade with a simpler design, lower cost, and less maintenance.

Best For: Projects that only require a single output size, or when screening will be done separately.

- Closed-Circuit Plants: Material passes through the crusher and then a screen, with oversize returned for re-crushing, producing a consistent size distribution and better product quality.

Best For: Projects needing precise aggregate grading for concrete, asphalt, or high-value construction materials.

Additional Screening and Conveyor Options

- Vibrating Screens & Adjustable Decks: Separate material into multiple size fractions, allowing different product sizes in one setup.

- Conveyors & Hydraulic Folding Systems: Reduce manual stockpiling and enable fast transport and setup.

- Feeders & Pre-Screening: Remove fine materials before crushing, reducing wear and preventing blockages.

Best For: Projects that require multiple product sizes or frequent adjustments between crushing stages.

Intelligent and Remote Control Systems

- Automation & PLC Control: Monitor load, output size, and production rates in real time, automatically adjusting settings to protect the machine.

- Remote Monitoring: Track performance, fuel consumption, and maintenance from anywhere, reducing downtime and labor needs.

- Plant Integration: Can connect with batching or screening units for seamless workflow on large or multi-site projects.

Best For: Projects needing consistent product quality with reduced labor and operational oversight.

Customization for Material and Project Needs

- Crusher Attachments: Optional impactors, cone liners, or VSI devices allow processing of different materials efficiently.

- Dust & Noise Control Modules: Enclosed feeders, water sprays, and noise-reducing covers ensure compliance with environmental regulations.

- Power Options: Diesel, electric, or hybrid drives provide flexibility depending on site power availability and operating costs.

Best For: Projects with specific material types, environmental requirements, or variable power conditions.

Check flexibility by looking at the circuit design, screening and conveyor options, automation, and how well the plant can adapt to different materials or environments. A flexible mobile crusher plant fits your project better, reduces downtime, and increases ROI.

Step 5: Review Key Performance and Efficiency Metrics

Before you make a final decision on a portable crushing plant, take a moment to look closely at its performance and efficiency. These factors will shape your daily output, operating costs, and long-term profits. By focusing on clear, measurable indicators, you can confidently compare different options and choose the one that truly fits your project.

Throughput and Material Handling Capacity

Actual throughput, measured in tons per hour (TPH), determines if a plant can meet your daily or project-wide production goals. Feeder size, crusher inlet dimensions, and conveyor capacity also influence material flow. Typical ranges: small plants 20–80 TPH, medium 80–250 TPH, large 250+ TPH. Ensuring the plant can handle your required capacity prevents bottlenecks and project delays.

Fuel Consumption and Energy Efficiency

Operating costs are heavily influenced by fuel or energy use, measured in liters per ton (L/t) or kWh per ton. Diesel plants offer mobility but may consume 3–5 L/t, while electric or hybrid models can reduce consumption by 15–30%, lower emissions, and run quieter. Look for features like auto-idle or load-sensing hydraulics for additional efficiency.

Ease of Maintenance and Spare Parts Availability

Routine maintenance is key to reducing downtime. Check for easy access to wear parts, centralized lubrication, and user-friendly diagnostics. Also, make sure spare parts are readily available. Typical maintenance intervals range from 50–100 operating hours for lubrication or inspections. Easy maintenance reduces unexpected costs and keeps projects on schedule.

Crusher Wear Parts Life Expectancy

Jaw plates, hammers, cones, and liners wear over time, affecting maintenance cycles and costs. Using high-quality materials and proper configuration can extend the lifespan of key components. Jaw plates and hammers typically handle 2,000–5,000 tons of material, while cones and liners can process 3,000–6,000 tons, depending on the hardness of the material. Harder materials may reduce lifespan, while softer or less abrasive materials can last longer. Plants with wear indicators or alerts allow proactive planning and prevent costly downtime.

System Reliability and Stability

Evaluate key components and manufacturer specs for mean time between failures (MTBF) or guaranteed operational hours (e.g., >1,500 hours). Bearings, hydraulic systems, and engines should provide consistent, stable operation. Reliable systems reduce breakdown risk and protect project timelines.

Step 6: Budget, ROI, and Long-Term Value

Choosing the right mobile crushing plant means balancing the upfront cost with long-term benefits. By considering total cost of ownership and projected ROI, you can make sure your investment keeps delivering value throughout its lifespan.

Initial Investment vs. Total Cost of Ownership (TCO)

The purchase price is only the starting point. True toal cost of ownership includes installation, transportation, operator training, and expected component replacements over the crushing plant’s lifetime. Choosing a high-quality machine can reduce unexpected expenses and improve operational reliability, offering better financial performance over time.

Estimating Return on Investment (ROI)

ROI depends on the mobile plant’s throughput, material value, and operational efficiency relative to TCO. By projecting gross margin per ton × expected production, you can compare how different models generate profit over time. This approach highlights the long-term financial impact of higher upfront investment versus lower-quality, cheaper alternatives.

Resale Value and Asset Depreciation

Well-built modular mobile plants can often keep 30–50% of their original value after 3–5 years, depending on maintenance and market demand. Plus, machines with upgrade-friendly or modular designs let you adapt to new projects, extend the equipment’s economic life, and get better long-term ROI.

Step 7: Choose a Trusted Manufacturer or Supplier

Reliable support really makes a difference when choosing a mobile crusher unit. Beyond just product quality, a good manufacturer or supplier will guide you, answer your questions, and help every step of the way. Working with the right partner means your plant runs smoothly and consistently meets your project goals.

Why Manufacturer Support Matters

- Installation Guidance: Proper setup reduces early breakdowns and helps your plant reach optimal performance quickly.

- Operator Training: Ensures safe, efficient use of the equipment while minimizing errors and accidents.

- Ongoing After-Sales Support: Includes troubleshooting, maintenance advice, and warranty coverage, safeguarding your investment over the long term.

Global Service Networks

- Quick Access to Parts and Technicians: Mobile plants often operate in remote or challenging locations, making fast support crucial to avoid costly downtime.

- Extensive Service Networks: Mobile crusher manufacturers with local or regional service centers can respond quickly. Andamine, for example, has branch offices in Indonesia, Malaysia, the Philippines, Uzbekistan, and Russia, along with multiple service outlets worldwide to support the customers.

- Genuine Spare Parts: Availability of original components ensures reliable maintenance and prevents delays in operations.

What Makes a Manufacturer Reliable

A dependable manufacturer combines quality crushing equipment with responsive service:

- Flexible configurations to match different project scales.

- Durable, easy-to-maintain designs built for long-term use.

- Advanced features such as automation, energy efficiency, and remote monitoring.

- Responsive technical support and operator training programs.

Request Case Studies and Customer Feedback

Before you make a final decision, don’t hesitate to ask for case studies or customer testimonials. Hearing how the plant performed on projects like yours gives real insights into reliability, service, and day-to-day operation—things specs alone just can’t show.

Partnering with a trusted manufacturer like Andamine—with a proven track record, global service network, and positive customer references—ensures your mobile crusher delivers long-term value, consistent performance, and peace of mind.

In Conclusion

Take your project to the next level with a mobile crushing plant designed for reliability, efficiency, and long-term performance. Our advanced crushing equipment handle everything from recycled aggregates to quarry rock with ease, offering customized configurations and fast parts support to keep your operations running smoothly. Maximize productivity and ROI—contact our team today to find the mobile crushing solution tailored specifically to your site and material needs.