Are you still suffering from “poor particle size, high energy consumption and complicated maintenance“?The impact crusher is redefining the standard of “high-efficiency crushing” with the technological innovation of “collision rectification“: it can accurately control the particle size of the finished product, complete the medium and fine crushing in a single stage, and make the production line simpler and more cost-effective.

Next, I’ll take you to learn more about the impact crusher machine.

4 Core Advantages of Impact Crushers

Impact crusher stands out in the market competition, mainly relying on the following core advantages:

Excellent cubic particle shape control:

The impact crushing of impactor crushers and the mutual collision between materials naturally produce cubic particles with clear angles and low needle flake content. This particle shape is the gold standard for high-quality concrete aggregates and asphalt mixtures, significantly improving compressive strength and pavement durability.

High crushing efficiency:

High Crushing Ratio: The impact crushing machine can achieve a crushing ratio of 10:1 or even 20:1, which means that it can crush large pieces of material (e.g. 300-500mm) to a relatively fine size (e.g. 30-50mm) at one time, simplifying the process.

High flexibility:

Convenient Size Adjustment: No need to replace parts, just by adjusting the gap of the impact plate and/or changing the speed of the rotor, the size of the product can be changed in a wide range to adapt to different market demands.

Simple structure and easy maintenance:

Relatively simple structure: the mechanical structure of the impactor is relatively simple, which reduces the manufacturing cost and makes the maintenance (especially the replacement of wearing parts) more convenient and efficient.

So, how are these efficient and stable performances actually achieved? Next, we will start from the most basic working principle.

How Does the Impact Crusher Work?

Have you ever heard of someone losing over $100,000 per month due to frequent equipment breakdowns? Failed to meet the standards of aggregate shape the construction company fined? The core of the problem lies in not understanding the kinetic energy principle of the crusher! Impact crusher is not a simple impact, but a precise energy control science, which directly determines your equipment life, energy costs, and product premium ability. The impact crusher working principle is simply “kinetic energy conversion”:

- High-speed impact: After entering the crushing chamber, the material is violently hit by the solid plate hammers on the high-speed rotor.

- Kinetic energy release and secondary crushing: The material being hit by the plate hammers hits the impact plate on the top of the frame at a high speed. In the process, the material carries a huge kinetic energy instantly released, so that it breaks itself.

- Free collision and shaping: the crushed material particles collide with each other in the crushing chamber, or are hit by the plate hammer again during the rebound process. This ‘free crushing’ mechanism is the core of the impact crusher’s ability to produce good cubic particles.

- Size Adjustment: The gap between the impact plate and the end of the rotor hammers can be adjusted hydraulically or mechanically to effectively control the size of the final product. Adjustment of the angle of the impact plate can also affect the trajectory of the material in the chamber and the crushing effect.

Key Impact Crusher Parts:

- Rotor: the “heart” of the crusher, its structure, weight, speed and dynamic balance accuracy directly affect the crushing efficiency and equipment stability. Heavy rotor to provide greater impact kinetic energy.

- Plate Hammer: direct collision with the material, usually made of high chromium cast iron, composite ceramic inlay, and other wear-resistant materials.

- Impact Plate: It bears the secondary impact and participates in the shaping of the grain shape. The same need for high wear resistance, usually designed as a multi-stage or adjustable angle form, after wear can be turned around to use or replace. Heavy-duty impact plate systems can withstand higher impact forces.

Now, I believe you have gained a certain understanding of this type of equipment. Next, we will specifically introduce to you impact crushers with different features, which can precisely match your production needs.

Different Types of Impact Crushers For Sale

APF-H Hydraulic Impact Crusher

- Capacity: 100-500 t/h, Customizable

- Inlet Size(mm): ≤1000 mm

- Processed Materials: Medium and low hardness materials with a compressive strength not exceeding 250MPa.

- Advantages:

1.The design of the host draws on the advanced technology of Finland, adopting a heavy-duty rotor, which has a larger moment of inertia and stronger crushing force.

2.Hydraulic adjustment of the gap between the impact plate and the hammer is convenient and quick, which can effectively control the granularity of the material, and the shape of the granule is good.

3.High feeding efficiency. Large feeding opening can replace jawbreaker when used as coarse crushing, and the maximum feeding size can reach 1000mm.

4.Reduced downtime losses. Large calibre feed opening can effectively prevent rebar entanglement, which is very suitable for crushing construction waste materials.

APF Impact Crusher

- Capacity: 50-550 t/h, Customizable

- Inlet Size(mm): ≤500 mm

- Finished Products Size: 5 – 200 mm

- Processed Materials: Medium and low hardness materials with compressive strength not exceeding 250MPa, such as limestone, slag, and concrete etc.

- Advantages:

1.Multi-cavity uniform crushing, the material from large to small is repeatedly crushed in the first, second, and third impact chambers.

2.With large crushing ratio and adjustable discharge size, the crushing process is greatly simplified.

3.New wear-resistant materials make the service life of plate hammer, impact plate and liner plate longer.

4. Hydraulic or mechanical opening structure is available, which is convenient for overhauling and replacing wearing parts.

APY3-F Series Mobile Impact Crusher

In addition, we also offer mobile impact crushers with customizable production capacity designs. Depending on the different terrain conditions, there are also tire-type and crawler-type options available.

Our mobile impact crusher integrates automatic feeding, crushing, and screening functions, reducing the investment in additional equipment. The mobile impact crusher is highly suitable for short-term projects or those that require frequent site changes, especially for the crushing of construction waste. Here are the specific parameters for your reference.

| APY3-F Series Mobile Impact Crusher Specifications | ||||

|---|---|---|---|---|

| Models | APY3-1110F-S3 | APY3-1210F-S3 | APY3-1213F-S3 | APY3-1315F-S3 |

| Power (kw) | 199.9 | 202.4 | 270.4 | 346.5 |

| Capacity (t/h) | 50-110 | 70-120 | 80-150 | 130-260 |

| Crusher Models | APF-1110F | APF-1210F | APF-1213F | APF-1315F |

| Max Feeding Size(mm) | 420 | 420 | 500 | 600 |

Which Industries Are Most Suitable for Impact Crushers?

So what industries are these different models used in? Impact crushers play an important role in a number of industries that require high material crushing accuracy and productivity.

Sand and Gravel Aggregate Production

Reason for application:

- Impact crusher is the core equipment for producing sand and gravel aggregate for construction (especially 12-31.5mm stone and 0-5mm mechanism sand), which is suitable for crushing medium-hard and brittle rocks.

- It can produce high quality cubic aggregate with high efficiency and meet the high requirements of mixing stations and key projects on aggregate shape.

Suitable materials:

- Medium hard and brittle rock: limestone, dolomite, sandstone, etc.

- Target products: 12-31.5mm specification stone, 0-5mm mechanism sand.

Economic Value:

- High-quality cubic aggregates are priced higher than ordinary aggregates, with significant market premiums (e.g., the price of mechanism sand is usually 10-30% higher than that of natural sand).

- Reduced transport costs (producing aggregates close by reduces long-distance transport costs).

Construction Waste and Demolition Waste Resourcing

Reason for application:

- Designed for processing construction waste (concrete blocks, bricks, etc.), stripping cement mortar through impact crushing and retaining clean aggregate.

- Ensure that the recycled aggregate particles are in good shape and can be directly used in the production of recycled building materials, enhancing the utilisation of resources.

Suitable materials:

- Construction waste: concrete blocks, bricks, tiles, waste pavement, etc.

- Target products: recycled aggregates (for recycled concrete, blocks, road base materials, etc.).

Economic Value:

- The cost of recycled aggregate is lower than natural aggregate, which can reduce the production cost of building materials by 15%-20%.

- Reduce the landfill cost of construction waste (landfill cost per tonne of construction waste is about $50-80), while creating revenue from recycled resources.

Mines & Mining Industry (Primary/Secondary Crushing)

Reason for application:

- Suitable for medium and fine crushing of metal ores (iron ore, copper ore, etc.) and non-metallic ores (limestone, gypsum, etc.), with flexible adjustment of crushing chamber design.

- The “stone to stone” or “stone to iron” mode avoids over-crushing, improves ore processing efficiency, and reduces equipment wear.

Suitable materials:

- Metal ores: iron ore, copper ore, lead-zinc ore, etc.

- Non-metallic ores: limestone, gypsum, quartzite, etc.

- Target products: 50-100mm or smaller particle size ores (to meet the feed requirements of ball mills, flotation machines, and other subsequent equipment).

Economic value:

- Reduce the waste of resources caused by over-crushing (over-crushing will reduce the ore grade by 10-15%).

- Enhance the recovery rate of mineral processing (such as iron ore recovery rate can be increased from 70% to more than 85%), reduce the unit cost of ore processing.

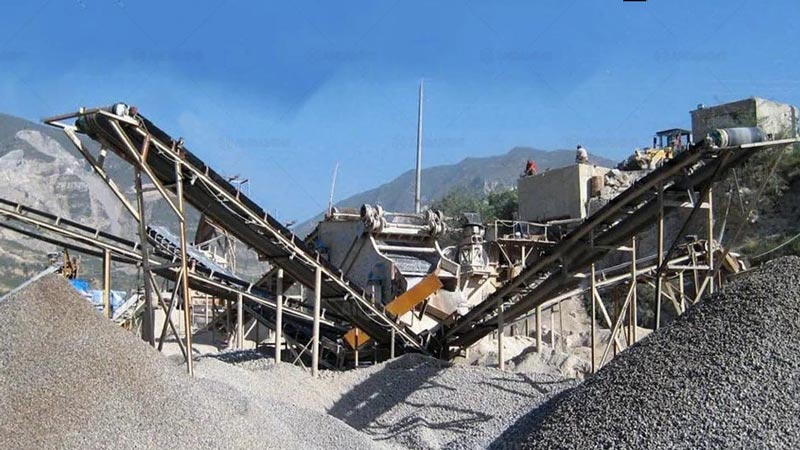

Practical Applications – Andamine Impact Crusher In Site Crushing

Andamine, impact crusher supplier in China, has been selling crushers for more than 40 years. Our crushers have been practically used in building construction, sand and gravel aggregate production, mining, construction waste crushing and many other projects. Below are impact crusher working pictures from our customers’ feedback.

Mobile Impact Crusher Used For Producing Concrete Aggregate

- Capacity: 150T/H

- Finished Product: 0-5 mm

- Project Site: in Colombia

- Main Configuration: Vibrating feeder, impact crusher, vibrating screen, belt conveyors,etc.

- Customer Feedback:

We used the Andamine impact type mobile crusher in the project to produce concrete aggregates. This equipment is not only highly efficient but also easy to operate. The PLC remote control system has provided great convenience for our construction project.

Mobile Impact Crusher Plant For Construction Waste Recycling

- Capacity: 150T/H

- Crusher Type: Mobile Crawler Type

- Finished Product: 5-20mm

- Project Site: in the Philippines

- Main Configurations: tracked impact crusher, vibrating screen, etc.

- Customer Feedback:

This mobile type impact crusher has been a great help to our construction waste recycling project, not only improving resource utilization, but also significantly reducing transportation cost.

Impact Crusher Crushing Limestone Materials In Quarry

- Capacity: 150T/H

- Output Aggregate Size: 20-40 mm

- Crusher Type: Stationary Type

- Project Site: in Malaysia

- Main Configurations: Jaw crusher, vertical shaft impactor crusher

- Customer Feedback:

In the high-intensity working environment, this impact crusher still maintains stable performance and excellent wear resistance, reducing equipment failure and downtime. This mobile crusher plant has greatly improved our production continuity and overall efficiency.