Ore beneficiation is the process of separating valuable minerals from waste materials using methods such as gravity, flotation, or magnetic separation. It enhances ore quality, increases economic value, and reduces environmental impact. Essential in the mining industry, beneficiation improves mineral concentration and purity. This article explores the raw materials, processes, techniques, and key benefits of ore beneficiation.

Key Raw Materials for Ore Beneficiation

Ore beneficiation is applied to a wide range of minerals. Some of the most common ores include:

- Iron ores: Hematite and magnetite are the primary iron-bearing minerals. These ores are widely used in the steel industry, and beneficiation helps to increase iron content while reducing impurities.

- Copper ores: Chalcopyrite and bornite are typical copper ores. Beneficiation improves the copper grade and removes sulfides and other gangue minerals.

- Bauxite: The main source of aluminum, bauxite requires beneficiation to remove silica, clay, and other impurities before smelting.

- Gold and precious metals: Gold ores often contain trace amounts of gold within sulfides or quartz. Beneficiation through flotation, gravity separation, or leaching improves recovery.

- Rare earth and lithium ores: These ores are critical for batteries, electronics, and renewable energy applications. Beneficiation ensures high-purity concentrates suitable for further processing.

Once the raw materials are identified, the next step is to understand which beneficiation methods are most suitable for treating them.

Ore Beneficiation Methods – Common Techniques

Ore beneficiation involves techniques designed to separate valuable minerals from gangue, enhance grade, and maximize recovery. The choice of method depends on mineral type, particle size, and impurities. Commonly applied techniques include:

Gravity Separation

Exploits density differences to concentrate heavy minerals such as magnetite, gold, and tin. Equipment like jigs, shaking tables, and spiral concentrators is often used. Gravity separation works well for coarse particles and is typically a preliminary concentration step.

Magnetic Separation

Separates magnetic minerals from non-magnetic gangue. Widely used for iron ores and other ferromagnetic materials, magnetic separators provide efficient, low-cost separation.

Flotation

Utilizes differences in surface chemical properties to separate minerals. Valuable minerals attach to air bubbles and float, while gangue sinks. Flotation is effective for sulfide ores like copper, lead, and zinc, as well as certain gold and rare earth ores.

Leaching

Dissolves valuable metals into a solvent, commonly used for gold, silver, and uranium. Cyanidation for gold and sulfuric acid leaching for copper are standard industrial processes. Leaching is particularly useful for fine or disseminated ores.

Froth Flotation for Fine Minerals

For very fine particles, chemicals make target minerals hydrophobic, allowing attachment to bubbles. This enhances recovery for complex ores, including some rare earth and lithium minerals.

Combination Techniques

Multi-step approaches, such as gravity separation followed by flotation, improve recovery and concentrate purity.

Advanced Methods

High-intensity magnetic and electrostatic separation are applied for rare earth and lithium ores, allowing precise separation of minerals with subtle magnetic or electrical differences.

After exploring the available techniques, it is important to see how these methods are applied in practice through a step-by-step process.

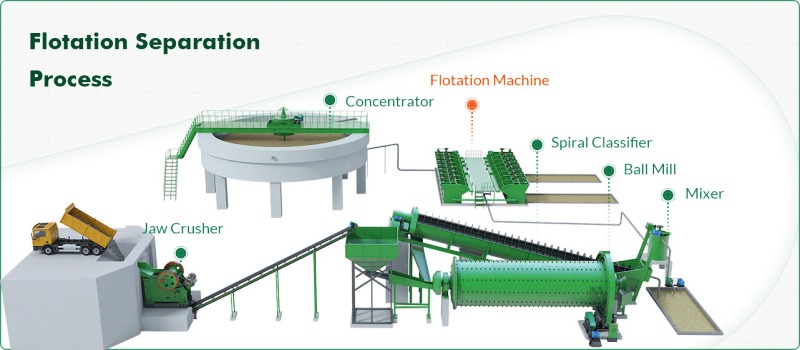

Step-by-Step Process of Ore Beneficiation

The ore beneficiation process is composed of several stages, each designed to efficiently separate valuable minerals from gangue:

1. Crushing and Grinding

Large ore chunks are reduced to fine particles using crushers and mills. Proper particle size is essential for effective separation in later stages. Andamine provides different crusher machines and ball mills to suit different ores crushing requirements.

2. Screening and Classification

Vibrating screens, sieves, and cyclones are used to sort crushed material by size. Proper classification ensures that ore particles are within the optimal range for the chosen beneficiation method, improving separation efficiency.

3. Concentration/Separation

Valuable minerals are separated from waste materials using physical or chemical techniques. Depending on the ore, this may involve gravity separation, magnetic separation, flotation, or leaching, resulting in enriched mineral concentrates.

4. Dewatering and Tailings Management

Concentrates are dewatered using filters, thickeners, or presses. Tailings are carefully managed to minimize environmental impact, following sustainable mining practices.

5. Optional Process Steps

Additional treatments, such as chemical processing or bio-beneficiation, may be included depending on the ore type and desired purity of the final product.

A well-designed beneficiation plant integrates each stage into a smooth, stepwise workflow, often illustrated with a flow sheet diagram. While this process ensures maximum recovery, high concentrate quality, and efficient use of equipment, its success also depends on several efficiency factors that directly influence the overall outcome.

Factors Affecting Ore Beneficiation Efficiency

The efficiency of ore beneficiation depends on several interrelated factors that influence both recovery rates and overall plant performance:

Ore Mineralogy and Composition

The type, structure, and proportion of minerals in the ore determine how effectively they can be separated.

Liberation Size of Valuable Minerals

Proper grinding is essential to ensure minerals are sufficiently liberated for downstream recovery.

Selection of Beneficiation Method

Choosing between gravity separation, flotation, magnetic separation, or combined processes directly affects yield and concentrate purity.

Plant Design and Automation

Well-planned layouts, modern equipment, and automation systems improve consistency, throughput, and cost control.

Energy and Operating Costs

Efficient energy use and optimized operations determine not only technical performance but also the economic viability of the process.

These factors highlight that beneficiation success is not dependent on a single stage, but on a well-coordinated balance between ore properties, process design, and cost management. When efficiency is optimized, the process yields tangible benefits that extend beyond the plant itself and into the broader mining value chain.

Benefits of Ore Beneficiation

A properly optimized beneficiation process generates multiple benefits for mining companies and the industry as a whole:

Higher Ore Grade

Increasing the concentration of valuable minerals leads to more efficient smelting and refining downstream. Higher-grade concentrates improve overall production performance and reduce energy consumption during processing.

Reduced Transport and Processing Costs

Removing gangue materials lowers the total tonnage that needs to be transported and treated. This reduces energy use, transportation expenses, and processing costs, making operations more efficient and cost-effective.

Better Resource Utilization

Ores with lower grades, once uneconomical, can now be profitably processed. This reduces waste, extends the life of mineral deposits, and supports sustainable resource management.

Environmental Improvements

Effective tailings management, water recycling, and reduced dust emissions contribute to cleaner and more sustainable mining practices. These measures help companies meet stricter environmental regulations while reducing their ecological footprint.

Beyond improving economic performance, beneficiation promotes cleaner production and helps companies comply with environmental regulations. These technical and environmental gains also highlight the importance of evaluating economic outcomes, which are central to investment decisions in modern mining operations.

Economic Aspects: Cost, Efficiency, and ROI

Understanding the economic dimension is crucial when planning a beneficiation plant, as it directly affects both operational performance and long-term profitability.

Capital InvestmentEstablishing a beneficiation plant requires significant initial expenditure on essential equipment, including crushers, ball mills, separators, conveyors, storage facilities, and control systems. Careful planning and investment in reliable, efficient equipment are key to ensuring consistent operation and reducing long-term costs.

Operating CostsRecurring expenses such as energy consumption, chemical reagents, water usage, labor, and routine maintenance strongly influence overall profitability. Efficient cost management is essential to maintain competitive operations and optimize recovery rates while minimizing waste.

Return on Investment (ROI)The financial success of a beneficiation project depends on the value of the recovered concentrates. Higher recovery rates and improved ore grades often command better market prices, helping to justify the initial capital outlay and ongoing operational expenses.

With clear financial and operational benefits, it is important to explore how beneficiation supports various industries and shapes future mining trends.

Applications and Industry Outlook

While the economics of beneficiation determine investment decisions, its applications across industries highlight its long-term strategic importance.

Steel Industry

High-grade iron concentrates are indispensable for efficient steelmaking, ensuring lower fuel use and higher furnace productivity.

Renewable Energy Metals

Beneficiation of lithium, cobalt, and rare earth ores supports the fast-growing battery, electric vehicle, and electronics sectors.

Technological Trends

Integration of automation, AI-driven monitoring, and digital twin modeling improves plant efficiency, reduces downtime, and enhances process control.

Sustainability Focus

Energy-efficient separation methods, advanced water recycling, and eco-friendly tailings management are becoming industry standards as environmental regulations tighten.

Ore beneficiation is more than a technical step—it improves efficiency, maximizes resources, and supports sustainable mining. Using Andamine crushing equipment and ball mills helps mining operations achieve higher recovery, consistent concentrate quality, and smoother processing, making beneficiation more reliable and effective.