In most people’s traditional impression, the word “crushing” is always closely associated with dusty mines, deafening noise, and rough mining. However, with the rise of the global wave of circular economy and the in-depth promotion of the “double carbon” goal, the application of crushing equipment is experiencing a profound change.

It is no longer limited to the traditional mining field, but strides towards new energy, environmental protection, ecological restoration, and other diversified emerging fields. The expansion of this application scenario is essentially the embodiment of the precise match between technical value and social demand, which also brings unprecedented opportunities and challenges for the development of the crushing industry.

New Energy Industry: Crushing Technology Enables “Green Closed Loop”

In the booming development of the new energy industry, crushing technology plays a crucial role, helping to realise the “green closed loop” from resource extraction to product recycling.

Lithium Recycling

Power battery recycling faces 3 core challenges:

- 1.Battery shell contains aluminium/copper composite material, and traditional cutting is prone to burrs.

- 2.The bonding agent between modules leads to low separation efficiency.

- 3.Excessive impurity content affects the quality of recycled materials.

Solution:

- Adopt low-temperature freezing pretreatment technology to embrittle the binder and increase the crushing efficiency by 40%.

- Intelligent sorting module achieves 99.5% metal purity and ≤0.1% impurity content.

- Laminar crushing reduces energy consumption by 35%.

Photovoltaic Module Recycling

With the continuous development of the PV industry, the amount of PV module decommissioning is also increasing year by year.

PV module decommissioning generates new demand:

- In 2030, China’s PV module decommissioning volume will reach 2.8 million tonnes.

- For every 1% increase in wafer recycling rate, 3,000 tonnes of quartz sand mining can be reduced.

Technology breakthrough:

- Hot knife cutting technology achieves non-destructive separation of EVA film.

- The centrifugal separation system separates glass and silicon wafers with 99.2% purity.

- Crushing equipment capacity increased to 1.5 tonnes/hour.

Environmental Protection: Crushing Equipment to Build A “Waste-Free City”

In the context of environmental protection, crushing equipment has become a key tool for building “waste-free cities”, playing an important role in construction waste treatment and tailing pond management.

Resourcefulness of Construction Waste

With the acceleration of urbanisation, the amount of construction waste generated is increasing day by day. If a large amount of construction waste is arbitrarily landfilled, it will not only occupy land resources but also cause serious pollution to the environment. Therefore, construction waste resourceisation has become an inevitable choice for the sustainable development of cities.

Challenges

There are 3 major challenges in the treatment of construction waste:

- Complex composition: There are many complex components in construction waste, such as concrete, steel and wood.

- Low processing efficiency: insufficient capacity of traditional crushing equipment.

- Poor quality of recycled aggregate: excessive mud content affects the performance of building materials.

Innovative practice:

- Mobile crushing plant realizes the integration of “crushing-screening-removing impurities”.

- Double-axis shear separates metal and concrete, with a metal recovery rate of over 95%.

- The light material separator removes wood chips and plastic, and the qualified rate of recycled aggregate is increased to 85%.

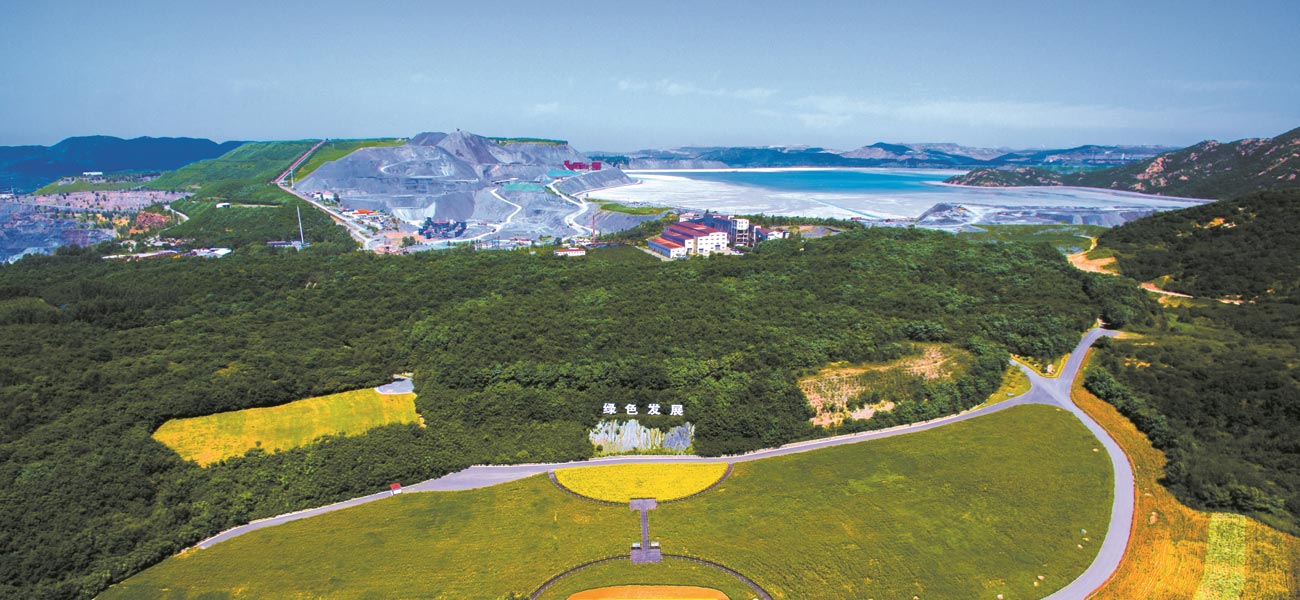

Tailings Storage Facility Management

Tailings storage is an important facility for mine production, but it also brings serious environmental problems. The accumulation of tailings in tailing ponds not only occupies a large amount of land, but also may cause natural disasters such as mudslides and landslides. Turning tailings into “solid waste” into “secondary resources” has become an important issue for the sustainable development of mines.

Challenges

Tailings disposal is under double pressure:

- Environmental risk: Tailings depots occupy more than 35,000 hectares of land globally.

- Waste of resources:The metal content of tailings reaches 5-10% of the original ore, resulting in a waste of resources and costs.

Technology path:

- High-pressure roller mills grind tailings to -200 mesh 70%.

- The “crushing-magnetic separation-flotation” co-production line improves the metal recovery rate by 22%.

- Recycled aggregate preparation of permeable bricks with water permeability exceeding 10,000L/m²-s.

Eco-Restoration: Fragmentation Technology for “Natural Reconstruction”

In the field of ecological restoration, crushing technology also has a wide range of application prospects, providing innovative solutions for desert management, forestry residue utilisation and so on.

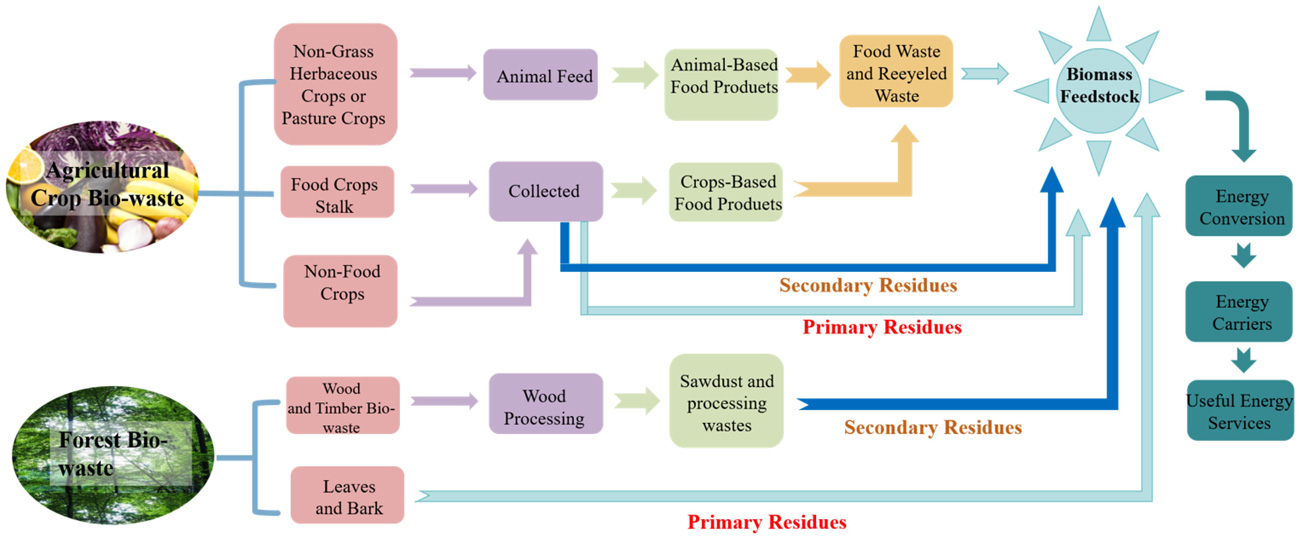

Forestry Residue Utilisation

The forestry production process generates a large amount of residues, such as wood chips and branches. In the past, these residues were often incinerated, which not only wasted resources but also produced a large amount of pollutants. Traditional crushing equipment consumes high energy and utilises less than 30%. Nowadays, crushing technology opens a new way for high value utilisation of forestry residues.

Calorific value enhancement technologyBiomass crushing and pelletising technology, calorific value increased to 4500kcal/kg.

High organic matter fertiliserPine needles crushing and preparation of organic fertiliser, organic matter content of 65.

Energy saving and consumption reductionEnergy consumption of crushing equipment is reduced by 40%, with significant carbon emission reduction.

The crushed wood chips and branches can be used to make biomass pellets to replace standard coal, which has significant energy-saving and emission reduction effects. Some projects can reduce CO₂ emissions by up to 100,000 tonnes per year after applying this technology. In addition, crushed pine needles can also be used to prepare organic fertiliser, which has a high organic matter content, improves soil structure, and promotes plant growth.

Desert Management

Desert management is a difficult and complex task in which crushing technology plays a unique role. By crushing gravel and mixing it with grass species for spraying, sand can be effectively fixed, and the survival rate of vegetation can be improved.

3 Major Obstacles

- Vegetation cover is less than 15 per cent owing to the low survival rate of vegetation.

- Sand particles are highly mobile, making sand fixing materials expensive investments.

- Traditional grass square structures last only between 3-5 years.

Breakthrough technology:

- Crushed gravel + bio-based cement preparation of sand fixing substrate;

- Jet crushing equipment to achieve sand consolidation, the vegetation survival rate increased to 85%.

- Comprehensive treatment cost is reduced by 60%, and the cost of sand consolidation per mu is ≤800 yuan.

In some sand management projects in Inner Mongolia, the use of this broken gravel + grass seed injection technology successfully completed 2000 acres of sand curing. The application of this technology not only improves the ecological environment of the desert area, but also brings a positive impact on the local economic development and residents’ lives.

Market Opportunities and Technical Challenges

The application of emerging fields brings broad market opportunities for the crushing equipment industry, but it also faces some technical challenges.

Emerging Track Growth Data

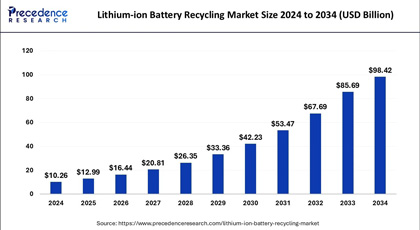

Lithium recycling:

In the field of lithium recycling, the rapid growth of the market size is remarkable. It is expected that by 2025, the global power battery crushing market size will exceed $12 billion, with a compound annual growth rate of 35%. This growth is mainly due to the continued expansion of the new energy vehicle market and the continuous improvement of battery recycling policies.

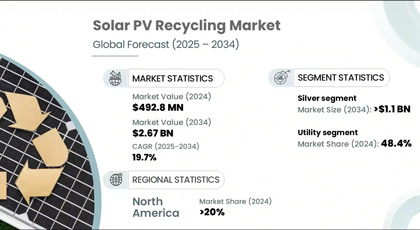

PV module recycling:

The PV module recycling market also has great potential. With the increasing amount of PV module decommissioning, it is expected that by 2025, China’s PV module recycling market size will reach 2 billion yuan, with a compound annual growth rate of 40%. The growth of this market will drive the demand for related crushing equipment, providing a broad space for the development of equipment manufacturing enterprises.

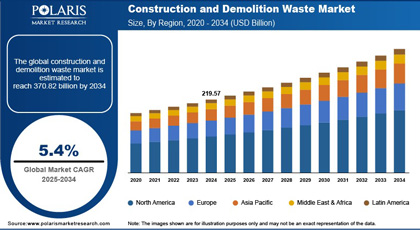

Construction waste treatment

With the continuous expansion of urban scale and the promotion of construction waste resourceisation policy, the market scale of construction waste treatment is expanding. This will further expand the market demand for crushing equipment such as mobile crushing plants and light material separators.

Technical Adaptability Challenges

Despite the promising prospects of the emerging market, crushing equipment also faces the obstacle of technical adaptability in the application process.

- The nature of materials varies greatly: such as metals, composite materials, brittle minerals, etc., the hardness, toughness, structure, etc. of these materials are different, the parameters of the crushing equipment requirements are also different. Therefore, the development of crushing equipment that can adapt to diversified material processing has become an important issue for the industry.

- High crushing cost: Small and medium-sized enterprises often face greater pressure in the balance between cost and efficiency. High-end crushing equipment, although superior performance, but expensive, small and medium-sized enterprises procurement pressure. How to ensure the performance of the equipment under the premise of reducing costs and improving the cost-effectiveness of the equipment is another key issue that the industry needs to address.

Future Development Strategies for Crushing-Related Companies

Facing the opportunities and challenges of the market, crushing equipment enterprises need to formulate a reasonable development strategy and actively respond to future trends.

Technology R&D

Business Expansion

Policy Utilisation

From metal mines to photovoltaic power plants, from urban construction to desert management, the expansion of the application scenarios of crushing equipment has brought new opportunities and challenges for the development of the industry. Enterprises need to follow market trends, strengthen technological innovation, rational use of policy resources, and actively respond to various challenges in order to be invincible in the wave of the circular economy and achieve sustainable development.