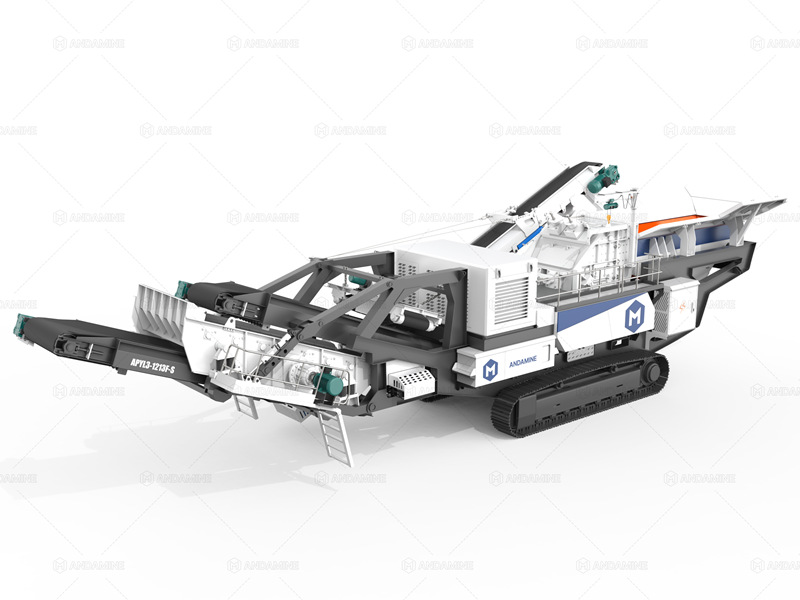

A mobile impact crusher is a highly efficient mobile crushing equipment that integrates feeding, crushing, and conveying. It utilizes a crawler or tire chassis and can be driven directly to the job site without transportation. It is adaptable to complex terrain (such as mines and demolition sites) and is primarily used for material crushing in areas such as construction waste recycling, mining, highway construction, and building materials. It offers unparalleled flexibility and is suitable for projects requiring frequent relocation and on-site processing, significantly reducing operating costs and time.

Suitable Materials and Application Scenarios for Mobile Impact Crushers

Mobile impact crushers excel at processing medium-hard to hard materials, particularly those with lower abrasiveness. Their versatility makes them ideal for various applications where on-site processing and mobility are crucial. The following table outlines common material types and their typical application scenarios:

| Material Type | Characteristics | Primary Application Scenarios |

|---|---|---|

| Construction & Demolition Waste | Concrete, bricks, asphalt fragments; variable size and composition | Urban demolition projects; Building renovation sites; Road rehabilitation projects |

| Limestone & Medium-Hard Rock | Natural sedimentary rock; relatively low abrasiveness | Quarry secondary crushing; Aggregate production for construction; Railway ballast production |

| Recycled Asphalt | Milled asphalt pavement; requires precise sizing | Road repair and resurfacing projects; On-site RAP (Recycled Asphalt Pavement) production; Highway maintenance operations |

| Industrial By-products | Slag, glass, ceramics; often irregular shapes | Industrial site cleanup; Mining operation support; Manufacturing waste processing |

The mobility and quick setup of these mobile impact crushers make them particularly valuable for people working on multiple sites or in urban environments where space is limited and operational efficiency is critical.

Mobile Impact Crushers Based on Types of Chassis

Mobile impact crushers are primarily available in two configurations: track-mounted and wheel-mounted designs. Each type of mobile impact crusher for sale from ANDAMINE serves distinct operational needs and job site conditions, offering unique advantages in mobility, stability, and application suitability.

Track-Mounted Mobile Impact Crushers

Track-mounted crushers are the preferred choice for demanding environments and complex projects where terrain accessibility and full mobility are critical. These units are designed with a reinforced tracked undercarriage that provides exceptional ground stability and enables operation on challenging surfaces, including soft, uneven, or sloped terrain.

Key Features & Advantages:

Wheel-Mounted Mobile Impact Crushers

Wheel-mounted mobile impact crushers provide an efficient crushing solution for projects that benefit from easy transport between sites and rapid setup capabilities. These units are designed with a focus on road mobility and quick deployment.

Key Features & Advantages:

- Easy Transport Configuration: Designed with standard trailer connections and road-compliant lighting systems, enabling straightforward towing behind prime movers between different project locations.

- Rapid Deployment: Simple setup process with hydraulic support legs that stabilize the unit quickly, minimizing the time between arrival at site and beginning production.

- Cost-Effective Operation: Lower maintenance requirements and reduced fuel consumption compared to track-mounted units, offering excellent value for operations with multiple accessible sites.

- Stable Performance: Engineered chassis with well-distributed weight provides reliable operation on prepared surfaces and established work platforms.

- Flexible Positioning: Maneuverable design allows for optimal placement on site to maximize production efficiency and material flow.

Ideal Applications of Mobile Impact Crushers

Track Mounted Type’s Ideal Applications:

- Rugged terrain and remote job sites

- Large-scale demolition and recycling projects

- Quarry operations and mining applications

- Infrastructure projects requiring frequent relocation

- Sites with limited infrastructure and difficult access

Wheel Mounted Type’s Ideal Applications:

- Urban construction projects with paved access

- Multiple-site operations with road connections between locations

- Temporary crushing requirements at fixed, prepared sites

- Municipal road construction and maintenance projects

- Recycling operations at established facilities with good infrastructure

Both track-mounted and wheel-mounted mobile impact crushers offer valuable solutions for different operational requirements. Track-mounted units excel in challenging terrain and remote locations, while wheel-mounted crushers provide efficient mobility and quick setup for projects with good road access and prepared sites. The selection between these configurations should be based on specific project conditions, mobility needs, and operational preferences.

How a Mobile Impact Crusher Works: From Mobility to Crushing Process

Mobile impact crushers combine exceptional mobility with advanced crushing technology, making them ideal for multiple-site operations. Here’s a comprehensive look at both their transportation capabilities and operational processes.

Transportation and Site Setup

The crusher’s mobility begins with easy transport between job sites. It can be driven short distances on their own power, while longer moves require low-bed trailer transportation. Upon arrival at the new site, the hydraulic support system deploys stability legs within minutes, and all conveyors are unfolded automatically. The entire setup process typically takes less than 30 minutes, allowing quick transition from transportation mode to operational readiness.

Material Feeding System

Once positioned, the crusher begins operation with controlled material feeding. A vibrating feeder with remote control capability regulates the flow of raw material from the hopper to the main conveyor. The integrated pre-screening grizzly section removes fine materials before they enter the crushing chamber, optimizing the crushing process and reducing unnecessary wear on components.

Impact Crushing Mechanism

The heart of the operation is the impact crushing chamber where material undergoes size reduction. A high-speed rotor rotating at 500-800 RPM accelerates material toward massive blow bars that deliver the primary impact force. The material is then thrown against adjustable impact aprons for secondary crushing. This dual-impact action, combined with inter-particle collision, ensures efficient reduction of even hard and abrasive materials.

Screening and Classification Process

After crushing, material moves to the integrated screening system through discharge conveyors. A vibrating screen with multiple deck options separates the crushed material into specified size fractions. Modern systems feature quick-change screen meshes that allow operators to adapt to different product requirements without extended downtime.

Closed-Circuit Operation

Oversized material that doesn’t pass through the screen returns to the crusher via a recirculation conveyor. This closed-loop system ensures consistent product quality by continuously reprocessing material until it meets the required specifications. The automatic regulation system monitors crusher load and adjusts the feed rate accordingly to maintain optimal performance.

On-Site Mobility and Repositioning

During operation, the track-mounted system allows for minor repositioning without complete shutdown. Operators can use the radio remote control to move the crusher closer to the material source or optimize positioning for better material flow. This feature is particularly valuable in large sites where the material source location may change during the project.

Production Control and Monitoring

An advanced PLC system continuously monitors all operational parameters, including production rates, power consumption, and component status. Operators can adjust settings from the touchscreen control panel or via wireless remote control. The system provides real-time data on production performance and maintenance requirements, enabling proactive operation management.

Shutdown and Relocation

After completing work at a site, the system enters a controlled shutdown sequence. All conveyors fold hydraulically into transport position, and the crusher is raised from its operational stance. The automated transport mode ensures all components are securely locked for safe movement to the next job site, typically within 1-2 hours including setup time at the new location.

This balanced approach to mobility and crushing operation makes mobile impact crushers exceptionally versatile equipment that maintains high production standards while offering the flexibility to work across multiple sites efficiently.

Project Spotlight: 150 TPH Construction Waste Recycling in Colombia

A construction company in Bogotá needed to efficiently process over 500 tons of daily construction and demolition waste while complying with Colombia’s strict environmental regulations. Their goal was to transform concrete, asphalt, and brick debris into reusable aggregates for local construction projects. We provide them solution with reasonable mobile impact crusher price:

Our Solution

We provided the APY3-F mobile impact crusher plant, specifically configured for:

150 TPH processing capacity

Hybrid power system (diesel/electric) for fuel efficiency

Advanced dust control meeting local environmental standards

Track-mounted design for easy site mobility

Key Results

Within the first 12 weeks of operation:

Processed 80,000+ tons of construction waste

Achieved 95% material recovery rate

Reduced transport and disposal costs by 40%

Met all local environmental compliance requirements

Client Feedback

“The mobile crusher transformed our waste management approach, eliminating landfill costs while creating new revenue streams from recycled materials.” Carlos Rodríguez, Project Director.

Sustainable Value: Environmental Benefits in Construction Waste Recycling

Mobile impact crushers transform construction and demolition (C&D) waste into valuable resources directly at job sites, delivering both environmental benefits and economic returns through sustainable practices.

Environmental Impact Reduction

Landfill Diversion: On-site processing diverts up to 90% of C&D waste from landfills, significantly reducing environmental burden

Carbon Emission Reduction: Eliminates transportation to distant recycling facilities, reducing CO₂ emissions by approximately 40% compared to conventional methods

Resource Conservation: Transforms waste concrete and asphalt into high-quality recycled aggregates, reducing natural resource extraction

Economic Advantages

Revenue Generation: Recycled aggregates command growing market value while costing 30-40% less than virgin materials

Cost Reduction: Dramatically reduces transportation and landfill costs, with some operators saving over $150,000 annually

Regulatory Compliance: Helps meet growing environmental regulations while qualifying for green incentives and tax benefits

Global Regulatory Alignment

Mobile crushing solutions align with international sustainability mandates:

European Union: 70% C&D waste recycling requirement by 2025

North America: 75% recycling mandates in states like California

Asia-Pacific: Zero Waste initiatives across Singapore and Southeast Asia

Middle East: Sustainability pillars in Qatar’s National Vision 2030

Future-Proof Investment

Carbon Pricing: 40+ countries have implemented carbon pricing systems favoring on-site processing

Green Certification: LEED and BREEAM award points for construction waste recycling

Corporate Requirements: Major buyers increasingly demand sustainable practices from suppliers

Mobile impact crushers represent a strategic investment that combines immediate operational benefits with long-term sustainability leadership, helping construction businesses meet environmental regulations while improving profitability through waste valorization.

One-Stop Service for Your Mobile Crushing Needs

At ANDAMINE, we as one of the best mobile impact crusher manufacturers provide complete end-to-end solutions for your mobile impact crusher operations, ensuring maximum productivity and return on investment from initial consultation to long-term operation.

| Pre-Sales Consultation & Planning |

|

| Custom Manufacturing & Quality Assurance |

|

| Global Logistics & Commissioning Support |

|

| Comprehensive After-Sales Support |

|

| Continuous Improvement Partnership |

|

ANDAMINE mobile impact crushers are supported by a global service network that ensures professional support wherever your projects take you. From initial consultation to long-term operation, we partner with you to ensure your crushing operations achieve maximum productivity and return on investment.

Contact us today to discuss your mobile crushing requirements and discover how our complete service package can support your success.