The mobile crushing plant is a key piece of equipment in the mining, construction and aggregate production industries, and its ability to move flexibly and process on-site has made it popular in the industry. However, its frequently mobile nature and the reality of operating at high intensity in harsh environments all year round poses a severe test for the various components of the equipment.

Proper maintenance can ensure personnel safety, optimise productivity and reduce equipment failure rates. So how to carry out the maintenance of mobile crushing plant? Please see below:

Crushing System Maintenance

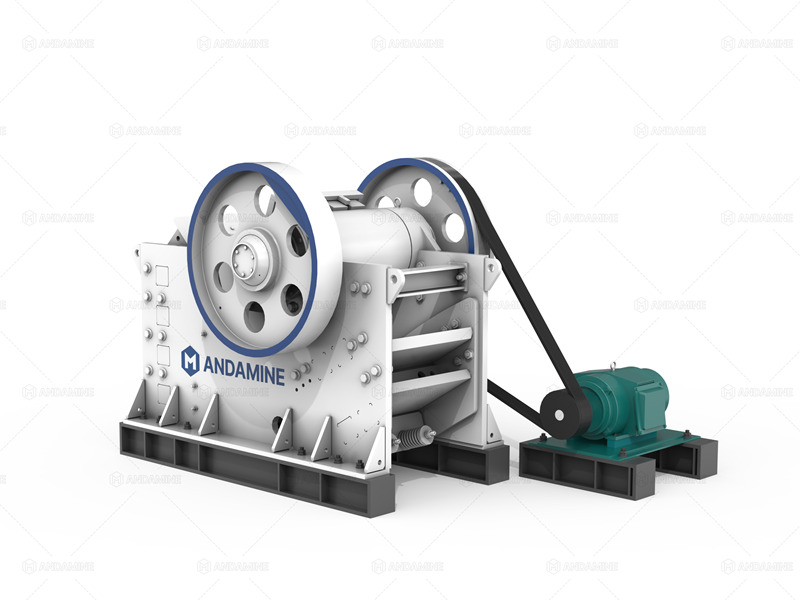

1. Jaw crusher maintenance

Dynamic jaw assembly:

- Check the wear of jaw plate daily (wear >30% needs to be replaced).

- Check elbow plate for cracks every week.

- Measure bearing temperature every 100 hours (normal <75℃).

Adjusting device:

- Check the wear of adjusting wedge iron every week.

- Measure the size of discharge opening every month (error ±2mm).

Drive train maintenance

- Weekly check the belt tightness (press down amount of 10-15mm is normal).

Replace in groups if cracks or severe wear are found (new and old belts should not be mixed).

2. Cone Crusher Maintenance

Crushing chamber:

- When replacing the liner plate, the bolts need to be tightened symmetrically in sequence (in 3 increments of torque to the standard value).

Check liner bolts for anti-loosening marks every shift (retighten if displacement is found). - Use ultrasonic thickness gauge to measure the critical part of the liner plate every week (the thinnest part is ≥60% of the original thickness).

Hydraulic system

- Monthly sampling and testing of hydraulic oil contamination (qualified up to NAS 9).

- Change the hydraulic oil every 2000 hours or annually (flush the tank before changing the oil).

Spindle and Bearing

- Monthly use a percentage meter to measure the spindle runout (standard value 0.2-0.4mm).

- Adjust or replace the thrust bearing if it exceeds the standard value.

- Combined with vibration analysis to determine the health of bearings (vibration value of a sudden increase of 10% need to stop the machine to check).

3.Impact crusher maintenance

Daily Inspection:

- Daily inspection of rotor surface wear (focusing on hammer disc edges).

- Monitor hammer wear with a thickness gauge (maximum wear allowed ≤ 20% of original thickness).

- Check the rotor balance block fastening bolts (torque needs to reach the manufacturer’s standard value ±5%).

Bearing maintenance:

- Daily monitoring of bearing temperature (double-row roller bearing temperature alarm value of 85 ℃).

- When centralised lubrication system is used, special grease (NLGI grade 2) should be replenished every 8 hours.

- Disassemble and check bearing clearance every 500 hours (axial clearance ≤ 0.3mm).

Screening System Maintenance

Our training covers the full lifecycle of your crushing operation, including:

Sieve Mesh:

- Check the screen mesh tension (deflection ≤ 5mm).

- Weekly inspection of screen mesh breakage (breakage rate>5% need to be replaced).

Chain conveyor:

- Check chain tightness every shift (sagging 20-30mm).

- Weekly check of sprocket tooth wear.

Shaker:

- Daily check the bearing temperature (normal <70 ℃).

- Replenish grease every week.

- Replace bearing grease every 500 hours.

Belt conveyor:

- Daily inspection of belt deflection (deflection ≤5% of bandwidth).

- Check the roller bearing condition every week.

- Monthly measurement of belt wear.

Power system maintenance

1. Diesel engine maintenance

Daily maintenance:

- Check oil level daily.

- Drain fuel filter water every shift.

- Check fan belt tension weekly.

Regular Maintenance:

- Change oil and filter every 250 hours.

- Clean intercooler every 500 hours.

- Check injector atomisation every 1000 hours.

2. Hydraulic system maintenance

Hydraulic Oil Management:

- Monthly sampling and testing of oil (contamination level NAS 9 or less).

- Change hydraulic oil every 2000 hours or annually.

- Maintain oil temperature in the range of 30-60 °C.

Critical Components:

- Check cylinder seals weekly.

- Check accumulator precharge pressure monthly.

- Clean hydraulic tank breather quarterly.

Electrical System Maintenance

1. Control cabinet maintenance

Daily check:

- Daily check the status of each indicator light.

- Monthly measurement of grounding resistance (≤ 4Ω).

Component maintenance:

- Quarterly cleaning of contactor contacts.

- Annual testing of insulation resistance (≥ 1MΩ).

2. Sensor maintenance

Material level sensor:

- Weekly cleaning of the detection surface.

- Monthly calibration of measurement accuracy.

Temperature sensor:

- Quarterly comparison with standard thermometers.

- Replace immediately if deviation >5% is detected.

Specialised Maintenance Related to Mobile Characteristics

There are two types of mobile crushing plant structure, tyre type and track type, for different chassis structures. I summarise the following points:

Tyre-type mobile crushing plant

Tyre management

- Air pressure: test and adjust according to the standard value before and after each transfer (too high is easy to burst the tyre, too low exacerbates the wear).

- Wear inspection: regularly detect tread depth, cuts, bulges and abnormal bias wear (suggesting positioning problems).

- Wheel bearings: adjust preload according to the cycle, replenish high temperature grease to prevent overheating damage.

Travelling system

- Brake safety: Regularly check the brake fluid level and thickness of pad/shoe wear to ensure braking efficiency.

- Steering lubrication: Regularly lubricate the tie rod ball head and steering knuckle, and check the leakage of hydraulic steering system.

- Towing device: check the wear of towing pin, reliability of locking mechanism, lubrication of outrigger screw.

Crawler-type mobile crushing plant

Track system

- Tensioning: Adjust daily or after turnaround according to manual standards (too tight accelerates wear, too loose is prone to derailment).

- Wear monitoring: Regularly check for broken track plates, elongated chain track joints, chipped drive wheel teeth, and oil leaks from outrigger wheels.

- Cleaning and lubrication: Remove debris and mud between tracks; sealed tracks need to be regularly filled with specified grease.

Travelling structure

- Undercarriage inspection: check the deformation and cracks of the travelling frame, and tighten the connecting bolts.

- Motor Maintenance: Monitor the oil level and leakage of the travelling gearbox, and change the cycle gear oil.

Finally, don’t forget to keep a detailed record of every maintenance performed, including the date, running time, maintenance items, consumables used (oil, cartridge, grease type), parts replaced, and problems found.

Maintenance of mobile crushing plant is an effective way to avoid unplanned downtime, control operating costs, maximise equipment ROI and guarantee production continuity. Don’t forget to perform regular maintenance! And, if you use the Andamine mobile crushing plant, its IOT system can automatically remind you to carry out the maintenance of the equipment, so you don’t have to record the frequency of maintenance manually.