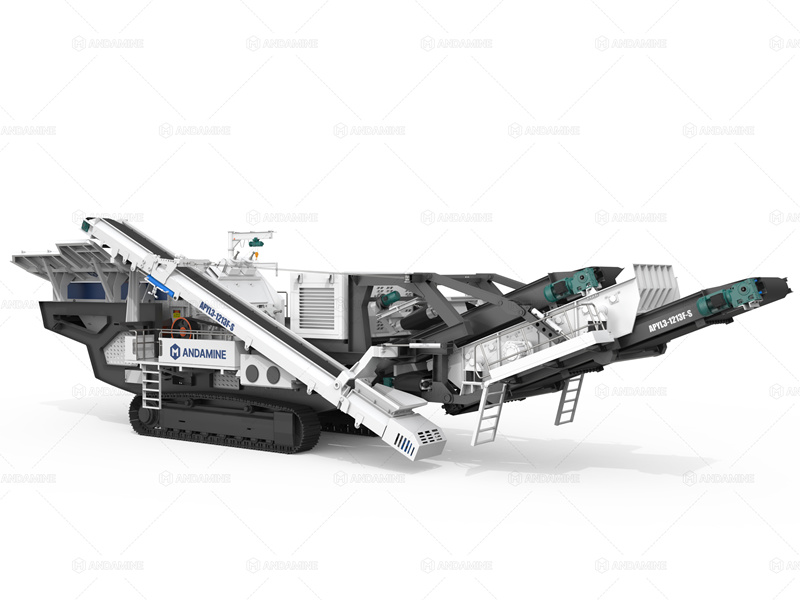

Mobile impact crushers are important crushing machine for construction, mining, waste recycling industries. The mobile impact crusher’s working process includes moving to the site, fixing to the ground and ensure stability, crushing, screening, closure and moving away.

Move & Adapt to the Site: Tracked vs. Wheeled Systems

The fundamental advantage of mobile impact crushers begins with their ability to rapidly deploy to any worksite. We provide two distinct mobility systems, each engineered for specific operational environments:

The APY series wheel-type mobile crusher exemplifies this engineering philosophy. Processing 100-350 tph of granite, basalt, or reinforced concrete debris, its containerized design minimizes transport disassembly. Vehicle-mounted radial stackers eliminate external conveyor logistics, while laser-aligned shoe plates provide instant stability on unprepared ground. The economic implications are profound: sites report 40% faster project starts and 30% reduced mobilization costs compared to traditional crushing plants.

Fix the Crusher & Ensure Stability

Operational stability transcends mere static weight distribution. During crushing, impact forces generate dynamic loads exceeding 200 G-forces at the rotor assembly. Modern crushers counteract this through multi-stage stabilization:

Tracked Systems utilize their entire undercarriage as a vibration-dampening mass. Cross-braced hydraulic cylinders lock the tracks into “ground engagement mode,” creating a footprint that distributes up to 25 tons/m² pressure evenly. Andamine’s crawler chassis mobile impact crusher has ski plate support, which increases ground contact area for enhanced stability.

Wheeled Units employ synchronized hydraulic stabilizers with pressure sensors. When detecting load imbalances during crushing, these automatically extend secondary supports in milliseconds, maintaining level tolerance within 0.5 degrees. Andamine wheel chassis mobile impact crusher has ROSTA elastic vibration support which is used to replace the traditional steel spring support structure, which has small irregular amplitude during startup and shutdown, short transition time and long service life.

Both systems integrate seismic-grade dampers between the crushing module and chassis. These viscous fluid-filled cylinders absorb high-frequency vibrations before they reach structural components, extending bearing life by 300% while reducing ground-transmitted noise by 15 dB(A).

Core Crushing Process

The crushing sequence begins with strategic material feeding. Mobile units typically receive material via excavator or wheel loader into a vibrating grizzly feeder. This 3-4 meter long prescreen section employs stepped grizzly bars that scalp off undersize material (0-50mm) before it reaches the crusher, boosting efficiency by 25%. The remaining feed enters the crushing chamber where transformative physics occur:

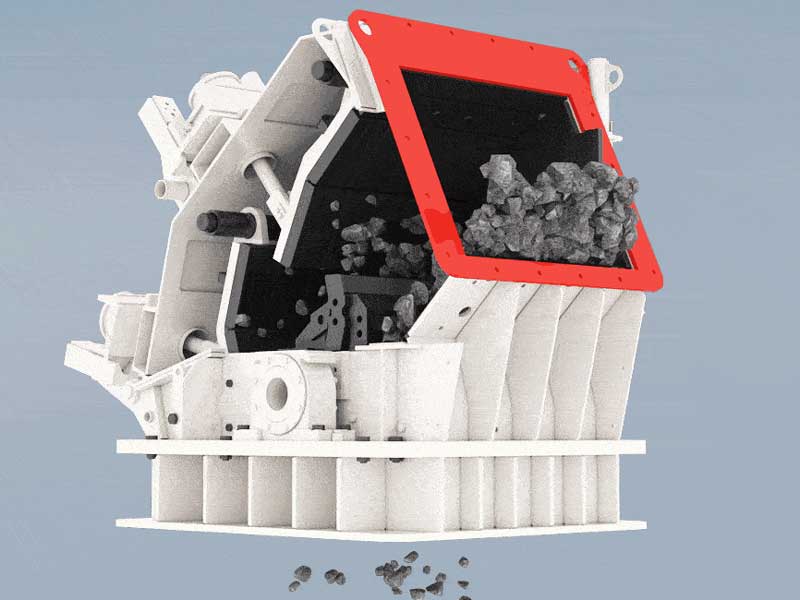

Impact Crushing Dynamics

At the chamber’s heart rotates a massive rotor assembly – typically a solid steel drum weighing 3-8 tons, balanced to micron-level precision. Mounted on its circumference are replaceable blow bars (hammers) crafted from chromium-molybdenum alloys (HRC 58-62). Driven by a 300-500 kW diesel-electric hybrid system, the rotor accelerates to 650-950 RPM, creating tip speeds of 45-70 m/s.

As material enters the chamber, it encounters three distinct fracture mechanisms:

- Direct Impact: Particles struck head-on by blow bars experience compressive stresses exceeding 250 MPa, shattering along natural cleavage planes.

- Accelerated Impact: Smaller fragments are hurled against adjustable impact aprons. These manganese steel plates (18-22% Mn content) are positioned to create optimal “stone-on-stone” collisions.

- Inter-particle Collision: Material ricocheting within the chamber creates secondary fragmentation, producing cubical grains ideal for concrete aggregate.

Intelligent Chamber Design

Modern crushers like the APY series feature hydraulically adjustable aprons with 150-400mm range. Operators fine-tune this gap in real-time via control panels, instantly modifying output size from coarse 80mm base material to 20mm finishing aggregate. Computational Fluid Dynamics (CFD)-optimized chamber geometries create controlled material trajectories, increasing residence time for complete reduction while preventing recirculation that causes wear.

Material Flow & Screening

Post-crushing material management showcases these systems’ true innovation:

- Primary Conveyor: A 1,200mm wide belt transports crushed material at 3.5 m/s to the screening module. Impact-resistant idlers with sealed spherical bearings maintain alignment despite heavy loads.

- Triple-Deck Screening: Vibrating screens employ precision-tuned eccentric masses generating 5-7g acceleration. Polyurethane screen media with trapezoidal openings achieve 98% separation accuracy:

- Top Deck (50-80mm): Returns oversize to crusher via closed-loop conveyor

- Middle Deck (20-50mm): Directs mid-size to stockpile

- Bottom Deck (0-20mm): Diverts fines to dedicated stockpile

- Radial Stackers: Hydraulic folding conveyors extend up to 15 meters, creating segregated stockpiles without repositioning. Automatic slew systems maintain continuous stockpile formation during operation.

Project Closure & Site Rehabilitation

The conclusion of crushing operations demonstrates mobile crushers’ environmental advantage. Demobilization begins with the “self-cleaning” sequence:

- Crusher reverses rotation for 60 seconds, ejecting residual material

- Conveyors run backward, discharging trapped particles

- Dust suppression systems flush residual fines from cavities

Tracked units retract stabilizers and depart under their own power. Wheeled crushers disengage stabilizers in under 10 minutes: hydraulic cylinders retract the chassis onto tires while conveyors auto-fold into transport position. Unlike fixed plants requiring concrete foundation removal, mobile units leave only compacted ground – often rehabilitated to original condition within hours.

Operational Impact Metrics

- Mobilization Speed: 45 minutes vs. 14 days for fixed plants

- Footprint Reduction: 70% less area than traditional crushing spreads

- Production Efficiency: 350 tph from a single operator station

- Environmental Compliance: 98% dust capture with integrated mist systems

The Mobile Crushing Revolution

Mobile impact crushers transform raw material processing through integrated engineering. From their terrain-conquering mobility to precision impact reduction and intelligent screening, they compress traditional multi-stage crushing circuits into singular, autonomous units. The Andamine APY series exemplifies this evolution – its wheeled configuration delivers quarry-grade production on urban job sites, while tracked variants conquer the most remote mineral deposits. Beyond mechanical innovation, these machines redefine project economics: eliminating concrete foundations, reducing fuel-intensive material haulage, and enabling contractors to monetize site-won materials previously considered waste.